Vibration Table

4.8 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

When the ..read more

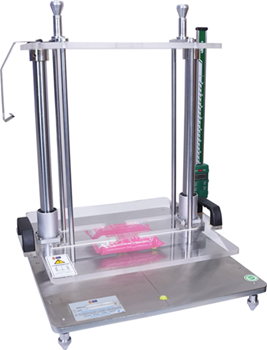

The vibration table from Presto is considered to be the top-quality testing instrument that is rigidly fabricated from the MS structure. The upper tabletop is suspended for vibration by bearing blocks. The main unit of this testing instrument contains cage, lever arm, motor unit, cable gland, cable, Grouting Slot, Locking Lever. It has a control panel that contains the main ON/OFF button with a connecting cable. To operate this testing instrument efficiently, you need to do a proper installation of the machine.

For this, you need to remove the wooden packing of the machine and place it on a good grade, reinforced concrete factory floor, which is at least 6” thick, which is adequate for a rigid connection of most vibration package testing machines.

Place the device by maintaining a clear distance between the machine and the control panel. Grouting of the machine needs to be done using the hex bolts as the machine vibrates at the time of the test procedure. Once you properly install this testing machine, then you can start with specimen preparation. You can take a filled corrugated box that you want to test and close all the sides of it by applying tapes on the sides to fasten them firmly.

After that, you can place the sample on this testing machine by slightly losing the hex bolt which is provided on the grill on the front side of the machine to open the grill. Close the grill and tighten the hex bolt. Once all these steps get completed, then you can easily commence the test. The machine is regulated through software with a built wi-fi system. Thus, you will be provided with a software CD and configure it to operate the machine well. You can also take help from experts like us to make sure that you can easily perform vibration testing of the products.

Features of Vibration Table

- Presto® Vibration tester is rigidly fabricated from MS structure.

- The upper tabletop is suspended for vibration by bearing blocks.

- The fixed amplitude of 25.4mm is generated using cam assembly.

- The frequency of vibration can be varied using the panel box from 2 Hz to 6Hz.

- Presto’s Vibration table helps to create repeated vehicle movement at an amplitude of 25mm along with the frequency of 120 strokes per minute.

- The machine has an intense cast iron base along with a separate control panel for long-lasting support.

- The apparatus is incorporated with a rail on the sides of the platform to fix the sample properly.

- The size of the vibration table is 0.5m x 0.5m (Customized size on demand).

Technical specifications

- Voltage Requirement: Single Phase 15 Amp. / 230 VAC Voltage

- Connection Type: 3 Pin Plug

- Grouting of Device: Hex Bolt Nuts

- Amplitude: 25.4mm

- Maximum Load Capacity: 100 Kg @ 6 Hz

- Body: Mild Steel Body

- Applications: Packaging Cartons, PET Bottles

- Time Range: up to 99.9 minutes

- Profile Programming: Four Profile Programming Parameters for Frequency Setting

- External Dimension: 820 X 820 X 980mm.

- Standard: ASTM D-999, TAPPI T-817-pm, IS7028 (part II)

Related Products

Laboratory Heat Sealer – (300mm)

Air Bulge Tester

Melt Flow Index Junior

Peel/Seal/Bond Strength Tester

For More details & Information

Please fill this form

Vibration Table

4.8 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

When the packages are transported then they are intended to simulate the vibrations and jolts. Thus, with the help of the Presto vibration table, you will be able to assess the performance of containers in terms of strength and protection. With the help of this testing instrument, you will be able to perform vibration testing of different structures and even calibration of dynamic transducers. Vibration simulation is a cost-effective and efficient technique to determine the damage that occurs with a product due to the recurring movements of the vehicles. In a duration of a few hours, we can easily detect the potentially damaged areas in the product that are occurring due to vibrations. Presto’s Vibration Chamber is ideal for consistency testing of compact goods and products. It is used as a separate table for vibration testing to offer the flexibility of a product. The instrument is used to produce continuous vibrations at an amplitude of 25mm along with the frequency of 120 strokes in a minute. The machine is built on rigid cast iron and equipped with a separate control panel. The machine is also equipped with railings on both sides of the sample platform to place the sample properly.

Whenever the package is ready for delivery, then it is important that the item inside the package should not get a break or be damaged when transported by road, rail, sea, and air. Due to these, the package is subjected to various vibrations and jolts of varying intensities. It is very difficult to simulate these vibrations in totality; however, the machine is designed to simulate these conditions closely in the laboratory. The vibration test provides means to determine in advance, under standard laboratory conditions, how a filled package will fare in a given distribution system. This test is used to assess the performance of containers only, in terms of their strength and the protection that it provides to the content when subjected to the vibrations during transportation.

There are different types of vibrations that occur in the product transportation process that will lead to product damage. It includes Synchronous vibrations, Non-Synchronous vibrations, and Vertical vibrations. The synchronous vibrations are those where both the cam assembly is in phase and the tabletop ends move simultaneously in a circular motion. Non-Synchronous OR out of phase is the one in which the cam assembly is not in phase with each other. One end of the table moves out of phase with respect to the other, in a circular motion. Vertical, that is, Table Top moves purely in up-down motion eliminating the lateral elliptical movement. The amplitude of vibrations will remain 25.4 mm, irrespective of the vibration mode selected on the machine.

The vibration table from Presto is considered to be the top-quality testing instrument that is rigidly fabricated from the MS structure. The upper tabletop is suspended for vibration by bearing blocks. The main unit of this testing instrument contains cage, lever arm, motor unit, cable gland, cable, Grouting Slot, Locking Lever. It has a control panel that contains the main ON/OFF button with a connecting cable. To operate this testing instrument efficiently, you need to do a proper installation of the machine.

For this, you need to remove the wooden packing of the machine and place it on a good grade, reinforced concrete factory floor, which is at least 6” thick, which is adequate for a rigid connection of most vibration package testing machines.

Place the device by maintaining a clear distance between the machine and the control panel. Grouting of the machine needs to be done using the hex bolts as the machine vibrates at the time of the test procedure. Once you properly install this testing machine, then you can start with specimen preparation. You can take a filled corrugated box that you want to test and close all the sides of it by applying tapes on the sides to fasten them firmly.

After that, you can place the sample on this testing machine by slightly losing the hex bolt which is provided on the grill on the front side of the machine to open the grill. Close the grill and tighten the hex bolt. Once all these steps get completed, then you can easily commence the test. The machine is regulated through software with a built wi-fi system. Thus, you will be provided with a software CD and configure it to operate the machine well. You can also take help from experts like us to make sure that you can easily perform vibration testing of the products.

Features of Vibration Table

- Presto® Vibration tester is rigidly fabricated from MS structure.

- The upper tabletop is suspended for vibration by bearing blocks.

- The fixed amplitude of 25.4mm is generated using cam assembly.

- The frequency of vibration can be varied using the panel box from 2 Hz to 6Hz.

- Presto’s Vibration table helps to create repeated vehicle movement at an amplitude of 25mm along with the frequency of 120 strokes per minute.

- The machine has an intense cast iron base along with a separate control panel for long-lasting support.

- The apparatus is incorporated with a rail on the sides of the platform to fix the sample properly.

- The size of the vibration table is 0.5m x 0.5m (Customized size on demand).

Technical specifications

- Voltage Requirement: Single Phase 15 Amp. / 230 VAC Voltage

- Connection Type: 3 Pin Plug

- Grouting of Device: Hex Bolt Nuts

- Amplitude: 25.4mm

- Maximum Load Capacity: 100 Kg @ 6 Hz

- Body: Mild Steel Body

- Applications: Packaging Cartons, PET Bottles

- Time Range: up to 99.9 minutes

- Profile Programming: Four Profile Programming Parameters for Frequency Setting

- External Dimension: 820 X 820 X 980mm.

- Standard: ASTM D-999, TAPPI T-817-pm, IS7028 (part II)