Drop Tester

4.67 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

Presto’s Drop Tester is designed as per IS: 7028, Part IV..read more

Features of Drop Tester

- It is highly consistent equipment for findings repeatable and accurate results.

- The testing instrumentis supplied with conformance certificate.

- Provision to uplift test platform by guide mechanism

- Drop Height adjustable clamp

- Straight and Angular Drop tests can be performed on a single Instrument

- Strong base plate with rugged structure

- Optional Features:

- Pneumatic model and in various platform sizes also available as per requirement.

Standards :

IS: 7028 Part IV

Technical specifications

- Height of the laboratory equipment is 1.8 meter (Adjustable).

- Higher height models are also available.

- Load can be exerted up to 50Kg.

- Maximum and Minimum height of drop is 1800 mm and 750 mm respectively.

- Sample Mounting table –465 * 445 mm

- Adjustable angle holder is provided with the device.

Type of tests:

- Straight Drop

- Angular Drop

- Safety: Locking pin

Related Products

Melt Flow Index - MFR Model (Method - A & B)

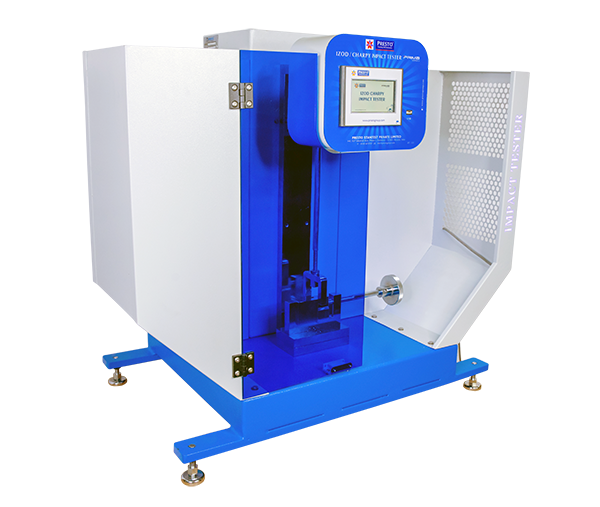

IZOD/Charpy Impact Tester NXG

TP800 Spectrophotometer

Puncture Tester for Films

For More details & Information

Please fill this form

Drop Tester

4.67 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

Presto’s Drop Tester is designed as per IS: 7028, Part IV standard. It is a useful instrument to determine the transport value of solid fibre boxes, corrugated boxes and shipping containers. It has an angular drop arrangement to correctly determine the transport worthiness of the package from all angles.

The drop test is performed to measure the ability of corrugated boxes and fibreboard cartons and containers to stand with vertical impact in free drops. The test is performed one time and more than one time to analyse various conditions that occur on a package during transit and handling. It serves as the best equipment for performance analysis and package design before production and use.

Reason for testing:

The drop test is performed to gauge the effect of shock in transit to avoid the progressive deterioration of products that can keep the product to be unused.

Drop tester is widely used in several industries to test and to substantiate the potency of corrugated boxes. The machine operates by dropping a test specimen from a certain height to ascertain the strength of the specimen. The testing equipment can be customized and made available in different specifications as per the demand of the customer.

Features of Drop Tester

- It is highly consistent equipment for findings repeatable and accurate results.

- The testing instrumentis supplied with conformance certificate.

- Provision to uplift test platform by guide mechanism

- Drop Height adjustable clamp

- Straight and Angular Drop tests can be performed on a single Instrument

- Strong base plate with rugged structure

- Optional Features:

- Pneumatic model and in various platform sizes also available as per requirement.

Standards :

IS: 7028 Part IV

Technical specifications

- Height of the laboratory equipment is 1.8 meter (Adjustable).

- Higher height models are also available.

- Load can be exerted up to 50Kg.

- Maximum and Minimum height of drop is 1800 mm and 750 mm respectively.

- Sample Mounting table –465 * 445 mm

- Adjustable angle holder is provided with the device.

Type of tests:

- Straight Drop

- Angular Drop

- Safety: Locking pin