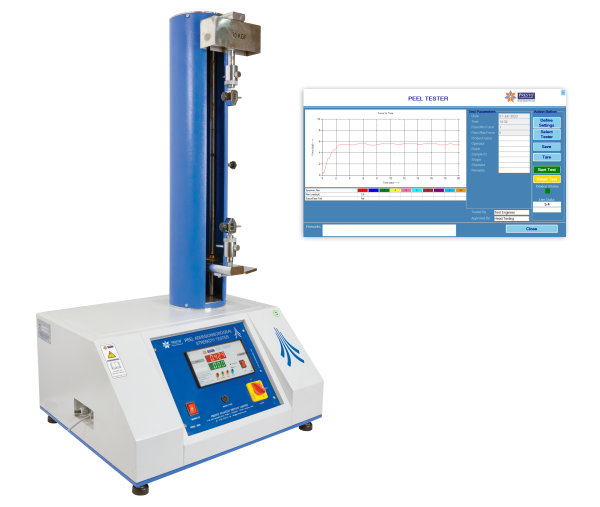

Peel Seal Bond and Adhesion Tester Digital cum Computerised Model

4.6 out of 5

Adhesive tape is a versatile, inexpensive material that plays an important role in the packaging industry. It provides essential functions such as sealing and holding things together. What if you put the poor quality of tape for packaging your products? It may lead to d..read more

The adhesive strength is a crucial factor in the quality of self-adhesive tapes and other related products. Adhesives are used in almost every industry to seal, bond, and stick together or attach different materials. However, it is important that they have adequate adhesion strength for their application. The peel testing instrument allows you to test the peel strength of various kinds of tape samples so that you can determine whether they will be suitable for your purpose or not. This helps to ensure high-quality standards and reduces wastage during production processes by avoiding faulty products from being put on sale. With our advanced peel tester machine, you can get accurate results that help improve efficiency while reducing costs at the same time. We offer this product at an affordable price range with fast delivery options. To know about the working of this testing instrument, you can follow the steps mentioned below:

To test the peel adhesion/bond or seal strength of the specimen, you need to prepare it first. You can do this by taking a self-adhesive tape that is 150mm long and 15 mm wide and preparing it as per the template provided with the machine.

Now dip one end of the strip into a toluene solution up to 25 mm. This will de-laminate that area of the strip. After that peel off the part of the strip that was dipped in toluene solution.

After performing the above-mentioned steps, you will have two ends of the strip that need to be placed in between the grips for testing. Your test specimen for the Peel adhesion test is ready.

Similarly, you can prepare the specimen for performing seal strength test and bond strength test.

To test the specimen accurately you need to operate the machine and place the specimen between the upper fixed grips and tighten the grip firmly. Now bring the lower movable grip upwards so that the specimen can easily reach the grips.

You must ensure that the lower limit switch ring is placed at a position that keeps a minimum distance of 25 mm. Now place the lower end of the specimen between the lower grips and tighten the grip firmly. Whenever you place the specimen between the two grips then you should make sure that the specimen should be placed in the center of the grips.

After performing all the above-mentioned steps, you can commence the test.

Peel tester is a simple way for companies to test the adhesion of their products quickly and easily without spending much time. It measures both peel adhesion as well as bond strength at different angles over multiple cycles. The data generated by this tester can be used for quality control purposes on production lines as well as QC labs across all industry verticals. The instrument comes with pre-programmed standards which makes it easy for anyone who has basic knowledge about measurement instruments to use this machine effectively and efficiently without any hassle or confusion whatsoever

Features of Peel Seal Bond and Adhesion Tester Digital cum Computerised Model

The adhesive strength of a product is an important factor that can decide its success in the market. If you want to test and measure how strong your products’ adhesives are, then you need to invest in Presto Peel Strength Tester. Here are some of the amazing features that you will get with the Presto peel tester.

- Microprocessor-based display for accurate test results

- Display for Peel Adhesive strength of test specimen

- Memory to hold up to 9 test reading

- Highly accurate test results under elongation force

- Bright LED display

- Feather touch controls with easy to operate functionality

- Advanced peak load indicator for accurate readout and storage of test results.

- Limit switches protection for the protection of grips and the machine.

- Powder-coated body with corrosion resistance.

- Available in different capacities as per client’s requirements

- High testing ranges from 5 kgf to 20 kgf.

Technical specifications

- Maximum Load range: 5 kgf to 20 kgf

- Grip to Grip Span: 300 mm

- Test Speed Range: 300 mm per min ± 5%

- Load Monitoring: Peak Load indicator with digital readout and peak hold feature

- Load Sensor: Universal Z-type Load Cell.

- Clamping mechanism: Vice type clamping Grips standard width-15 mm

- Load accuracy: ±0.5% full scale (with master load).

- Least count: 0.001 to 0.002

- Load Cell Over-load safety: <80% of the total load

- Safety Feature: Up and down fixed and movable mechanical limit switch.

- Over Load relay contact rating: Potential free relay 5 Amp. 220 V AC single phase

- Earthing Required: Proper Earthing required corresponding not more than 4 V AC with respect to neutral

Related Products

Drop Tester Motorized Pneumatic

Box Compression Tester Digital Mini

Tensile Testing Machine Computer Based -Zeus Ultimo

GSM Round Cutter

Peel Seal Bond and Adhesion Tester Digital cum Computerised Model

4.6 out of 5

Adhesive tape is a versatile, inexpensive material that plays an important role in the packaging industry. It provides essential functions such as sealing and holding things together. What if you put the poor quality of tape for packaging your products? It may lead to damage to products. Adhesive tape is an essential part of the packaging industry. It is used to seal boxes and packages efficiently. Therefore, considering the quality adhesive tapes is very necessary to keep the product damages away. You can easily test the strength of the specimen with no slippage and grips. This testing instrument is best for quality analysis of materials and products in QC labs as well as mainstream production chains. The instrument comes with no slippage grips for firm clamping of the test specimen.

The Peel Adhesion/Bond/Seal Strength Tester - Digital Cum Computerized is mainly used in industries and industrial laboratories for the purpose of studying the adhesion properties of various self-adhesive materials. The instrument is meant for creating high forces that are further used for various testing and analysis. The instrument is provided with a limit switch which acts as a safety feature for the machine and limits the movement of grips of the machine. The outer body of the machine is fabricated with mild steel which is duly powder coated. There is a digital peak load indicator provided with the instrument for a digital readout of the test results. The limit switch provided with the instrument is one of the best safety features that prevent the clashing of the grips.

With its easy operation and user-friendly interface, it makes testing very simple even for beginners who have no prior experience in using instruments like these before. The peel strength tester by Presto will provide you with a variety of options for testing the safety and quality of your product. As packaging industries have been integral in providing food, pharmaceuticals, or any other kind of goods that require examination on different levels before being sold to consumers this tool becomes invaluable as it ensures each label meets up-to-industry standards. Therefore, using Presto Peel Adhesion/Bond/Seal Strength Tester - Digital Cum Computerized model will help you to easily determine the adhesive strength of labels and tapes. The best part of using this testing instrument isn’t just how accurate they are but also all these features make them easy enough even beginners can use. Therefore, if you are searching for a reliable testing instrument to test the adhesive strength of materials, then we suggest you go with a Presto peel compression tester. Doing quality assurance of products will lead to increase profits and help to reduce product rejections. Therefore, with a Presto peel strength tester, you can easily perform the quality assurance of materials.

This testing instrument is highly recommendable for packaging industries. Many types of tapes are used in packaging industries for sealing purposes such as printed fragile tape, etc. A peel test is conducted to check adhesive strength between two flexible media underlaying the standard conditions. The strain rate varies depending on loading speed and temperature conditions within which these tests consist. There are many combinations possible including high-force fast peeling at lower temperatures than what you'd expect if using low force slower speeds over longer periods of time because their elongation has been reached while holding tension before applying any pressure against an object being sealed. Whenever you conduct a peel strength test with the help of the Presto Peel Compression Tester, then we suggest you not conduct this test with high peel force as it would lead to damage in the adhesives.

The main purpose of conducting this test is to check the adhesive between the two materials. Once you will be able to be sure about the product performance, then you can easily conduct safe usage of products. The common peel tests can be categorized as 90-degree peel tests, 180-degree peel tests, and T-peel tests. Therefore, it is very important for the packaging manufacturers to select the best and appropriate testing machine to understand simple geometry, size, and strength features. The peel tester from Presto consist of an easily operable contact button, high-tech digital controls, LED display, 20kgf capacity, and 0.001 kg resolution with the speed of .5kw with steel powder-coated paint. It has an inbuilt calibration technique that will help to set the machine according to the needs of the user. So, buy this testing instrument by calling us before it’s too late.

The adhesive strength is a crucial factor in the quality of self-adhesive tapes and other related products. Adhesives are used in almost every industry to seal, bond, and stick together or attach different materials. However, it is important that they have adequate adhesion strength for their application. The peel testing instrument allows you to test the peel strength of various kinds of tape samples so that you can determine whether they will be suitable for your purpose or not. This helps to ensure high-quality standards and reduces wastage during production processes by avoiding faulty products from being put on sale. With our advanced peel tester machine, you can get accurate results that help improve efficiency while reducing costs at the same time. We offer this product at an affordable price range with fast delivery options. To know about the working of this testing instrument, you can follow the steps mentioned below:

To test the peel adhesion/bond or seal strength of the specimen, you need to prepare it first. You can do this by taking a self-adhesive tape that is 150mm long and 15 mm wide and preparing it as per the template provided with the machine.

Now dip one end of the strip into a toluene solution up to 25 mm. This will de-laminate that area of the strip. After that peel off the part of the strip that was dipped in toluene solution.

After performing the above-mentioned steps, you will have two ends of the strip that need to be placed in between the grips for testing. Your test specimen for the Peel adhesion test is ready.

Similarly, you can prepare the specimen for performing seal strength test and bond strength test.

To test the specimen accurately you need to operate the machine and place the specimen between the upper fixed grips and tighten the grip firmly. Now bring the lower movable grip upwards so that the specimen can easily reach the grips.

You must ensure that the lower limit switch ring is placed at a position that keeps a minimum distance of 25 mm. Now place the lower end of the specimen between the lower grips and tighten the grip firmly. Whenever you place the specimen between the two grips then you should make sure that the specimen should be placed in the center of the grips.

After performing all the above-mentioned steps, you can commence the test.

Peel tester is a simple way for companies to test the adhesion of their products quickly and easily without spending much time. It measures both peel adhesion as well as bond strength at different angles over multiple cycles. The data generated by this tester can be used for quality control purposes on production lines as well as QC labs across all industry verticals. The instrument comes with pre-programmed standards which makes it easy for anyone who has basic knowledge about measurement instruments to use this machine effectively and efficiently without any hassle or confusion whatsoever

Features of Peel Seal Bond and Adhesion Tester Digital cum Computerised Model

The adhesive strength of a product is an important factor that can decide its success in the market. If you want to test and measure how strong your products’ adhesives are, then you need to invest in Presto Peel Strength Tester. Here are some of the amazing features that you will get with the Presto peel tester.

- Microprocessor-based display for accurate test results

- Display for Peel Adhesive strength of test specimen

- Memory to hold up to 9 test reading

- Highly accurate test results under elongation force

- Bright LED display

- Feather touch controls with easy to operate functionality

- Advanced peak load indicator for accurate readout and storage of test results.

- Limit switches protection for the protection of grips and the machine.

- Powder-coated body with corrosion resistance.

- Available in different capacities as per client’s requirements

- High testing ranges from 5 kgf to 20 kgf.

Technical specifications

- Maximum Load range: 5 kgf to 20 kgf

- Grip to Grip Span: 300 mm

- Test Speed Range: 300 mm per min ± 5%

- Load Monitoring: Peak Load indicator with digital readout and peak hold feature

- Load Sensor: Universal Z-type Load Cell.

- Clamping mechanism: Vice type clamping Grips standard width-15 mm

- Load accuracy: ±0.5% full scale (with master load).

- Least count: 0.001 to 0.002

- Load Cell Over-load safety: <80% of the total load

- Safety Feature: Up and down fixed and movable mechanical limit switch.

- Over Load relay contact rating: Potential free relay 5 Amp. 220 V AC single phase

- Earthing Required: Proper Earthing required corresponding not more than 4 V AC with respect to neutral