Humidity/Conditioning Test Chambers Deluxe Model

4.9 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

If you are working in the plastic, rubber or metal industry the..read more

When the testing specimen like metal will be used in environmental conditions, then it may come in contact with various environmental factors. The temperature and humidity are among the top of them. Thus, you need to make use of proper testing equipment like Presto humidity chamber, to assess the physical properties of the specimen. By evaluating the physical properties of the specimen, you can easily produce high-quality material for your customers. To operate this testing instrument, you need to first install this testing machine accurately. After that, you can turn the machine ON. If the water-level low LED” glows on the control panel then, it is required to fill water in the water reservoir present at the backside of the chamber.

Maintain the water of the machine by connecting the DM water line with the inlet port provided on the backside of the machine to fill the water. The side inlet connected to the water reservoir should always be ON. Connectivity of the water should not be stopped. It will auto-refill the water when required and automatically stop when the tank is filled completely. The side inlet connected to the water reservoir should always be ON. This will help to create the required level of humidity inside the chamber.

Once you follow all the steps, then you need to prepare the specimen. After that, you can operate the testing machine. When the temperature in the digital read-out is more than the SET temperature, the cooling process automatically gets started ON, to reach the SET point. With the help of a manual preset timer button, the user can set the time for how long the machine needs to be operated according to his/her choice.

Features of Humidity/Conditioning Test Chambers Deluxe Model

- Alarm system with buzz sound at the test end process

- Temperature sensing through PT-100 sensor

- Highly accurate test results under uniform temperatures and humidity levels in the chamber

- Digital Control for Humidity and Temperature

- High Grade-imported puff insulation

- Maximum Thermal Efficiency by insulation means.

- SSR based heaters

- Digital Preset timer with LED Display

- In-built Auto tuning function

- Water Level Indicator

- Equipped with rapid air circulation German imported fan for uniform and homogenous heating, cooling, humidity, de-humidity

- inside the chamber

- Inbuilt Calibration feature with reference to master PID controller

- Setting to RTD PT-100 sensor through advanced PID controller

- Auto stop feature to stop the machine at a set time

- Time totalizer to calculate the no. of Hours run by the instrument

- Reservoir water tank auto refilling (Float value arrangement)

Technical specifications

- Capacity: 150 litres

- Display: LED (Digital)

- Accuracy: Temp. ± 2ºC / Humidity ± 5%

- Least Count/Resolution Temp / Humidity: 0.1ºC / 1%

- Power: 15A, 220V , Single phase, 50 Hz

- Temperature Range: 15ºC to 60ºC

- Humidity Range: upto to 95% RH

- Timer: 999Hr (Changeable to Min. as per request)

- Water Level Low: Alarm output

Highlights:

- No. of Sample racks: 2

- Handle: Yes

- Wet Heater: 1 Kw, 1 no.

- Dry Heater: 500 Watt, 1 no.

- Temperature Sensor: 1 (PT-100)

- Humidity Sensor: 1 (RH)

- Movement Castor: Wheels

- Material: Stainless Steel (Inner & outer body)

- Finish: Stainless Steel combination finish for corrosion resistant

- Dimensions: Inner : 455 x 455 x 710 mm & Outer : 660 x 930 x 1515 mm

Related Products

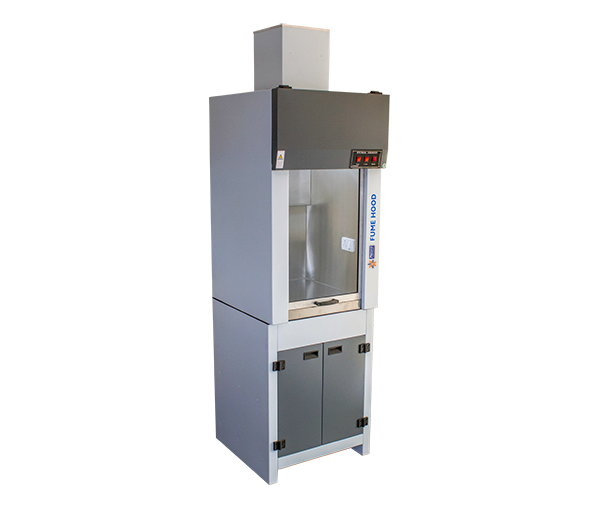

Fume Hood

PTH : Programmable Temperature & Humidity Test Chamber

Xenon Test Chamber PSPL 866

Salt Spray Chamber – Win series

For More details & Information

Please fill this form

Humidity/Conditioning Test Chambers Deluxe Model

4.9 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

If you are working in the plastic, rubber or metal industry then it is important for you to assess the physical properties of your product to improve its quality, then we suggest you go with Presto Humidity Chamber Deluxe Model.

This high-quality testing instrument provides quick temperature change rates and humidity conditions required for analyzing the effects of ecological changes on the product. The procedure of the equipment relies on the principle of accelerated environmental testing.

Presto’s conditioning test chamber is ideally designed with sophisticated technology to maintain designated temperature and humidity at set points controllable by the user at the front control panel. The Presto humidity chamber has been equipped with aerodynamically shaped fans for homogenous heating and cooling.

Air is constantly circulated throughout the chamber which can be easily monitored from the transparent glass for comparison to set points and can be treated if necessary. Heating is done by the electric heaters that can turn on and turn off for temperature control.

Purpose of using a humidity chamber

The main purpose of the humidity chamber is to assess different properties of the product under particular temperatures and humidity levels. This is because temperature conditions play a very important role in affecting product quality. You can effectively make use of this testing instrument for different industries like textile, fabric, metal, etc. The temperature and humidity are two parameters that will lead to failures of the product. Thus, you need to qualify these factors so that there will be no effect of the temperature and humidity on the product.

The Humidity/Conditioning Chamber Deluxe model maintains testing samples at a particular temperature and humidity level. The alarm system will be embedded with a buzzing sound at the test end process.

When the testing specimen like metal will be used in environmental conditions, then it may come in contact with various environmental factors. The temperature and humidity are among the top of them. Thus, you need to make use of proper testing equipment like Presto humidity chamber, to assess the physical properties of the specimen. By evaluating the physical properties of the specimen, you can easily produce high-quality material for your customers. To operate this testing instrument, you need to first install this testing machine accurately. After that, you can turn the machine ON. If the water-level low LED” glows on the control panel then, it is required to fill water in the water reservoir present at the backside of the chamber.

Maintain the water of the machine by connecting the DM water line with the inlet port provided on the backside of the machine to fill the water. The side inlet connected to the water reservoir should always be ON. Connectivity of the water should not be stopped. It will auto-refill the water when required and automatically stop when the tank is filled completely. The side inlet connected to the water reservoir should always be ON. This will help to create the required level of humidity inside the chamber.

Once you follow all the steps, then you need to prepare the specimen. After that, you can operate the testing machine. When the temperature in the digital read-out is more than the SET temperature, the cooling process automatically gets started ON, to reach the SET point. With the help of a manual preset timer button, the user can set the time for how long the machine needs to be operated according to his/her choice.

Features of Humidity/Conditioning Test Chambers Deluxe Model

- Alarm system with buzz sound at the test end process

- Temperature sensing through PT-100 sensor

- Highly accurate test results under uniform temperatures and humidity levels in the chamber

- Digital Control for Humidity and Temperature

- High Grade-imported puff insulation

- Maximum Thermal Efficiency by insulation means.

- SSR based heaters

- Digital Preset timer with LED Display

- In-built Auto tuning function

- Water Level Indicator

- Equipped with rapid air circulation German imported fan for uniform and homogenous heating, cooling, humidity, de-humidity

- inside the chamber

- Inbuilt Calibration feature with reference to master PID controller

- Setting to RTD PT-100 sensor through advanced PID controller

- Auto stop feature to stop the machine at a set time

- Time totalizer to calculate the no. of Hours run by the instrument

- Reservoir water tank auto refilling (Float value arrangement)

Technical specifications

- Capacity: 150 litres

- Display: LED (Digital)

- Accuracy: Temp. ± 2ºC / Humidity ± 5%

- Least Count/Resolution Temp / Humidity: 0.1ºC / 1%

- Power: 15A, 220V , Single phase, 50 Hz

- Temperature Range: 15ºC to 60ºC

- Humidity Range: upto to 95% RH

- Timer: 999Hr (Changeable to Min. as per request)

- Water Level Low: Alarm output

Highlights:

- No. of Sample racks: 2

- Handle: Yes

- Wet Heater: 1 Kw, 1 no.

- Dry Heater: 500 Watt, 1 no.

- Temperature Sensor: 1 (PT-100)

- Humidity Sensor: 1 (RH)

- Movement Castor: Wheels

- Material: Stainless Steel (Inner & outer body)

- Finish: Stainless Steel combination finish for corrosion resistant

- Dimensions: Inner : 455 x 455 x 710 mm & Outer : 660 x 930 x 1515 mm