Laboratory Heat Sealer – (300mm)

4.9 out of 5

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer Prima is used to measure the heat seal performance of composite films, plastic films such as PP, ..read more

Features of Laboratory Heat Sealer – (300mm)

Three different patterns of jaws are available: Plain, Straight line, Diamond Knurling.

- The force to be applied and the temperature range are adjustable.

- It is possible to adjust upper and lower jaws of the machine at different temperatures.

- The laboratory equipment is equipped with an imported P.I.D. temperature controller.

- The machine is completely microprocessor based with digital display.

Microprocessor-based display for accurate test results

- Highly accurate test results under pneumatic pressure control.

- Strong heating jaws for performing tests

- No slippage in case the specimen is placed uniformly without any loops.

- Bright LED display for temperature and timer

- PID temperature controller for highest level of controls and repeatability

- Digital Preset timer

- EN 31 hard and temper sealing jaw material

- Guide rod mechanism for efficient control of sealing

Standards: ASTM F 2029

Technical specifications

- Equipment Range: Ambient to 350ºC

- Sealing Temperature Working range: Ambient to 230ºC

- Temperature Controller : 4 digit PID

- Dwell Heat Seal time: 0.1–99.9 sec

- Timer: 3 Digit Digital

- Heat Sensor: Pt-100, Platinum Resistance Temperature Detector (RTD)

- Sealing Pressure: 6 Bar

- Temperature Controller : PID

- Timer: Digital Preset type

Related Products

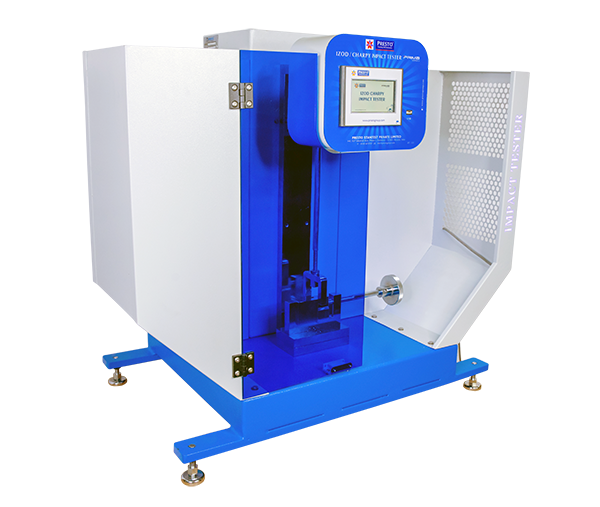

Izod / Charpy Impact Tester Computerized

IZOD/CHARPY Impact Tester

Drop Tester Motorized Pneumatic

IZOD/Charpy Impact Tester NXG

For More details & Information

Please fill this form

Laboratory Heat Sealer – (300mm)

4.9 out of 5

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer Prima is used to measure the heat seal performance of composite films, plastic films such as PP, PE used in packaging for different food products such as milk powder, instant noodle, food, washing powder, and drugs.

Presto’s Laboratory Heat Sealer Prima is widely used in packaging and plastic industry. It is a machine used to seal products like thermoplastic materials, packaging material using heat. Heat sealing helps to join two different materials, one of which consists of thermoplastic layer.

Heat Sealing is the process of sealing one thermoplastic material with another using pressure and heat together. The method of sealing utilizes a constantly heated sealing bar or die to apply heat to a specific contact path or area to weld the thermoplastic together. The laboratory heat sealer Prima is used for multiple applications like heat seal connectors, films, thermally activated adhesives, foil sealing or plastic ports.

The temperature of the machine is adjustable. It is a fully pneumatic model that has a digital display and based on microprocessors.

The heat sealer Prima is equipped with two jaws, i.e. lower jaw and upper jaw. Both the jaws of the machine can be heated separately with different temperatures and controllers. Hence, it is possible to maintain the temperature of both the jaws separately. It is possible to enable or heat one heater at a time, and it is also possible to switch off one heater in between while performing the test. The instrument is used to seal the plastic sample at the predetermined heating temperature.

Features of Laboratory Heat Sealer – (300mm)

Three different patterns of jaws are available: Plain, Straight line, Diamond Knurling.

- The force to be applied and the temperature range are adjustable.

- It is possible to adjust upper and lower jaws of the machine at different temperatures.

- The laboratory equipment is equipped with an imported P.I.D. temperature controller.

- The machine is completely microprocessor based with digital display.

Microprocessor-based display for accurate test results

- Highly accurate test results under pneumatic pressure control.

- Strong heating jaws for performing tests

- No slippage in case the specimen is placed uniformly without any loops.

- Bright LED display for temperature and timer

- PID temperature controller for highest level of controls and repeatability

- Digital Preset timer

- EN 31 hard and temper sealing jaw material

- Guide rod mechanism for efficient control of sealing

Standards: ASTM F 2029

Technical specifications

- Equipment Range: Ambient to 350ºC

- Sealing Temperature Working range: Ambient to 230ºC

- Temperature Controller : 4 digit PID

- Dwell Heat Seal time: 0.1–99.9 sec

- Timer: 3 Digit Digital

- Heat Sensor: Pt-100, Platinum Resistance Temperature Detector (RTD)

- Sealing Pressure: 6 Bar

- Temperature Controller : PID

- Timer: Digital Preset type