Dart Impact Tester – PRIMA SERIES

4.8 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

Testing t..read more

Features of Dart Impact Tester – PRIMA SERIES

This testing machine is compact and consistent and makes the use of force of falling dart that will actually rupture the plastic film under certain conditions. Thus, if you want to ensure the accurate testing results of a testing free-falling dart, then we suggest you go with our testing instrument. Here we have created a list of features of dart impact tester-Prima.

- Strong base plate with rugged structure

- User-friendly HMI-based Touchscreen model.

- Pass/Fail criteria can be programmed.

- Drop height adjustment clamp.

- Automation calculations & results through method setting as per the standard

- Easy data management. Users can create product identification, user name, magnet hold time, dart weight, percentage failure, etc.

- USB option for storing test data.

- Data output in data record format,

- The sample holding through pneumatic clamping.

- Clamping shield height-adjustable collar.

- Method setting for selecting test methods and performing the test.

- Electromagnetic hold and release mechanism for the dart to obtain accurate test results.

- Acrylic Shield to prevent the dart from falling out of the machine

- Automatic test through the electromagnetic lock

- Circular annular clamping with pneumatic connection for zero slippage.

Technical specifications

- Clamping Unit: Circular annular clamping unit with zero slippage

- Material: Mild Steel Duly Powder Coated/rugged /sturdy Aluminum construction

- Type of Test – Free Falling test

- Inner Diameter of the clamp: 127 mm

- Material of Dart's head: Special Silicate

- Release Mechanism: Electromagnetic dart hold/release mechanism through paddle switch

- Maximum attainable height of the dart: 660mm &1524 mm for methods A and B respectively.

- Diameter Of The Dart Head

- For Method A – 38 mm

- For Method B – 50 mm

- Length & Diameter of Method B dart: 226.5 mm & 50 mm ±1 mm

- Length & Diameter of Method A dart: 212.8 mm38 & mm ± 1 mm respectively

- Weight holding capacity: 2 kg.

- Least Count of height adjusting scale: 1 mm

- Pneumatic clamping Pressure: 3-4 Bars (Pneumatic supply in customer’s scope)

- Power: 220 V, 50 Hz, Single Phase.

- Control Panel: Digital Counter ( In- built-in HMI)

Related Products

Melt Flow Index Tester – Next Generation Model

Bench UV Light Accelerated Weathering Tester (Touch Screen)

Tensile Tester Servo

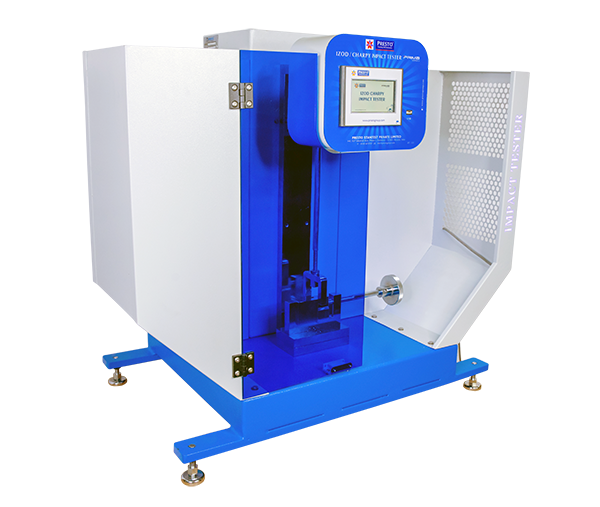

IZOD/Charpy Impact Tester NXG

For More details & Information

Please fill this form

Dart Impact Tester – PRIMA SERIES

4.8 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

Testing the strength of plastic films used in the packaging industry is of utmost importance. Not only does this help to increase productivity, but it can also save your business money. If you have a weak film that breaks during production or shipment, then there is damage to the product and/or equipment that will need to be fixed or replaced. Additionally, it is important for safety reasons that these products do not break when they are being used by consumers.

Thus, you can easily make the use of Presto dart impact tester-prima series to ascertain the strength of the plastic films that can withstand various forces levied on them. The testing instrument is provided with an electromagnetic dart hold or release mechanism to evade any type of interference in force exertion. This electromagnetic model of this testing machine can easily hold the weight up to 2kg. The instrument is also provided with user- friendly HMI display that helps to determine the effect of falls on the material which is performed in a single test. To clamp or unclamp the sample, a footswitch is provided with the machine. The pneumatic clamping which is provided with the machine is the top offer wrinkle-free clamping of the sample. Along with that, there is a protective shield device that is provided with the machine to prevent the dart from bouncing back, out of the machine.

This testing machine by Presto can easily determine the effect of free falling on plastic films and laminates. In this testing machine, the dart falls freely on the test sample under controlled conditions. Those who are working in the industries where plastic pouches, laminates, and other packaging materials are made can easily make use of this testing instrument by Presto. To perform this test, the sample is being prepared in accordance with testing standards. This will provide uniformity and precision in the test results. There are certain things that you should consider before beginning with the test. It is important to check whether the level of the machine is adjusted with a spirit level or not. You can also lock the leveling bots in the perfect position so as to assure that the apparatus will not vibrate. These things should be taken care of while you are performing a quality test for your product.

This testing instrument by Presto has been made with quality standard adherence and has been built as per the standards of International Standards Organization (ISO) and American Society for Testing and Materials (ASTM) standards that guarantee the generation of accurate results. This testing instrument is designed to offer the highest level of accuracy as well as precision consistently. This testing machine has been built with a rigid metallic base and is strong enough to stay last long. With its powder-coated mild steel material, there will be no chance of having corrosion on its body parts. This testing instrument is high in accuracy and is enhanced using an electromagnetic hold and release mechanism. To know more about this testing instrument including its price then we suggest you call us.

Features of Dart Impact Tester – PRIMA SERIES

This testing machine is compact and consistent and makes the use of force of falling dart that will actually rupture the plastic film under certain conditions. Thus, if you want to ensure the accurate testing results of a testing free-falling dart, then we suggest you go with our testing instrument. Here we have created a list of features of dart impact tester-Prima.

- Strong base plate with rugged structure

- User-friendly HMI-based Touchscreen model.

- Pass/Fail criteria can be programmed.

- Drop height adjustment clamp.

- Automation calculations & results through method setting as per the standard

- Easy data management. Users can create product identification, user name, magnet hold time, dart weight, percentage failure, etc.

- USB option for storing test data.

- Data output in data record format,

- The sample holding through pneumatic clamping.

- Clamping shield height-adjustable collar.

- Method setting for selecting test methods and performing the test.

- Electromagnetic hold and release mechanism for the dart to obtain accurate test results.

- Acrylic Shield to prevent the dart from falling out of the machine

- Automatic test through the electromagnetic lock

- Circular annular clamping with pneumatic connection for zero slippage.

Technical specifications

- Clamping Unit: Circular annular clamping unit with zero slippage

- Material: Mild Steel Duly Powder Coated/rugged /sturdy Aluminum construction

- Type of Test – Free Falling test

- Inner Diameter of the clamp: 127 mm

- Material of Dart's head: Special Silicate

- Release Mechanism: Electromagnetic dart hold/release mechanism through paddle switch

- Maximum attainable height of the dart: 660mm &1524 mm for methods A and B respectively.

- Diameter Of The Dart Head

- For Method A – 38 mm

- For Method B – 50 mm

- Length & Diameter of Method B dart: 226.5 mm & 50 mm ±1 mm

- Length & Diameter of Method A dart: 212.8 mm38 & mm ± 1 mm respectively

- Weight holding capacity: 2 kg.

- Least Count of height adjusting scale: 1 mm

- Pneumatic clamping Pressure: 3-4 Bars (Pneumatic supply in customer’s scope)

- Power: 220 V, 50 Hz, Single Phase.

- Control Panel: Digital Counter ( In- built-in HMI)