Box Compression Tester - Digital Cum Computerised

4.75 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: read more

If you want to test the compression strength of your corrugated box with the help of our box compression tester computerized cum digital model, then you need to start by preparing the specimen first. For this, you can take the corrugated box that you want to test and close all the sides of the corrugated box properly and apply tapes on the sides to fasten them firmly. Once you correctly prepare your testing specimen, then you need to start this testing machine by plugging it in 15 amp, 220 Volts AC. After that turn the machine ON. When the machine gets turned ON then place the specimen on the platform in the center and parallel to the compression plate. Make sure that the specimen is placed in the center of the plate otherwise the test results would not be correct. Mark points are provided. Bring the compression plate near the specimen by moving the rotary switch in a downward direction. Users can make use of the fast runner option to take the compression plate just above the test specimen with an increased speed of 50 mm/min. Apply a preload of 1 or 2 kgf on the specimen to remove any air gap between the compression plate and the specimen. After that, you can commence the test. For more information about how to set controls before testing your specimen, give us a call today.

Features of Box Compression Tester - Digital Cum Computerised

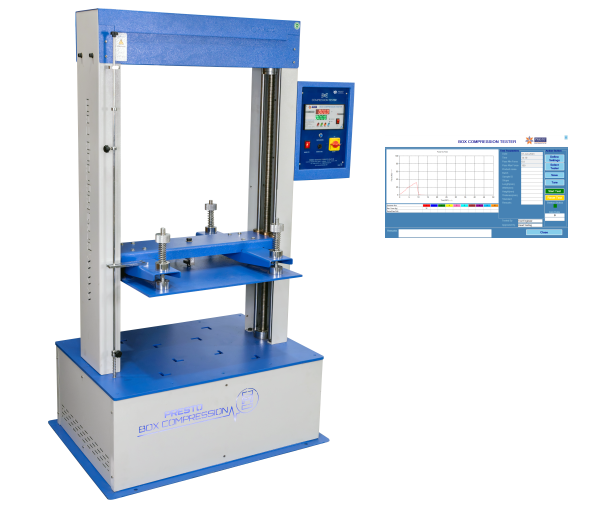

The box compression test is a quality control measure that should be standard in all packaging operations. Presto box compression tester has been made to test the specimen on a flat platform and pressing it down from top. The equipment is built on a rigid metallic base plate and finished in Autumn Gray & Blue combination painting and bright chrome / zinc plating to give it a corrosion resistant finish. You will get Instruction Manual, Electrical Wiring Diagram & Calibration Certificate traceable to NABL approved Labs with this testing instrument by Presto.

Here is the list of features for this model of box compression tester.

- High testing range

- Compression plates for proper placement of the test specimen.

- Compression nut provided with the machine to adjust the alignment of the compression plate.

- Micro-controller based peak load indicator for accurate readout and storage of test results.

- Limit switches protection for protection of grips and the machine.

- Powder coated body with corrosion resistance finish.

- Data can be tabulated in Excel

- Report has description of Product name , Operator , Batch , Shape , Standard ,Date , Time & Remarks

- Strong base plate with rugged structure.

- Feather touch controls

- 10 Sample test reports can be seen on one report

- Report Available in PDF format

- Easy Data Management. The user can create product identification, test details, etc.

Technical specifications

- Platform Size: 600 mm X 600 mm 1000 mm X 1000 mm

- Maximum Load range: 500 kgf and 1000 kgf

- Test Speed Range: 10 ± 2 mm/min

- Home position return Speed : 50 mm/min ± 10%

- Load Monitoring: Peak Load indicator with digital readout and peak hold feature

- Load Sensor: S-type Load Cell.

- Load accuracy: ±3% full scale (with master load.)

- Deflection: ±3% full scale

- Least count: 500 kgf- 200gm and 1000 kgf- 1 kgf

- Load Cell Over load safety: <80% of total load.

- Motor Power: 1 HP and 2 HP

- Motor Speed: 1350 RPM three phase motor.

- Safety Feature: Upward and downward fixed and movable limit switches

- Over Load relay contact rating: Potential free relay 5 Amp. 220 V AC single phase

- Main supply: 220 V AC single phase 50 Hz

- Earthing Required: Proper Earthing required corresponding not more than 4 V AC with respect to neutral

Related Products

Crease Stiffness Tester Prima Model

Dart Impact Tester – PRIMA SERIES

Spectrophotometer TP 3100

Vibration Table

For More details & Information

Please fill this form

Box Compression Tester - Digital Cum Computerised

4.75 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

Box compression tester is the most widely used tools in the packaging industry. It is used for testing the stacking load bearing capacity of the boxes. By determining the compressive strength of the box, the manufacturers can estimate the potential to sustain the warehousing and transportation conditions. Apart from cartons, it can be used to test the beehive crates, paper tanks, paper cases etc. Compressive strength further decides the weight range of the packing. The machine comes with a motorised arrange and can be used to perform the creep test or to adjudge the compressive strength of the box.

It is a very simple to operate machine and comes with computer connectivity. This means that this machine can be connected and operated with computer, dual communication. The machine comes with a rigid dual column structure and it has one movable plate. The specimen to be tested is kept in the platform and the movable plate applied a compressive force on the box. The load cell is used to apply the load. Sensors will determine the pressure that is exerted on the box. The electrical signals are processed and displayed on the bright LED scree in human readable form. The data can be logged and transferred in to the computer in graphical format.

If you want to test the compression strength of your corrugated box with the help of our box compression tester computerized cum digital model, then you need to start by preparing the specimen first. For this, you can take the corrugated box that you want to test and close all the sides of the corrugated box properly and apply tapes on the sides to fasten them firmly. Once you correctly prepare your testing specimen, then you need to start this testing machine by plugging it in 15 amp, 220 Volts AC. After that turn the machine ON. When the machine gets turned ON then place the specimen on the platform in the center and parallel to the compression plate. Make sure that the specimen is placed in the center of the plate otherwise the test results would not be correct. Mark points are provided. Bring the compression plate near the specimen by moving the rotary switch in a downward direction. Users can make use of the fast runner option to take the compression plate just above the test specimen with an increased speed of 50 mm/min. Apply a preload of 1 or 2 kgf on the specimen to remove any air gap between the compression plate and the specimen. After that, you can commence the test. For more information about how to set controls before testing your specimen, give us a call today.

Features of Box Compression Tester - Digital Cum Computerised

The box compression test is a quality control measure that should be standard in all packaging operations. Presto box compression tester has been made to test the specimen on a flat platform and pressing it down from top. The equipment is built on a rigid metallic base plate and finished in Autumn Gray & Blue combination painting and bright chrome / zinc plating to give it a corrosion resistant finish. You will get Instruction Manual, Electrical Wiring Diagram & Calibration Certificate traceable to NABL approved Labs with this testing instrument by Presto.

Here is the list of features for this model of box compression tester.

- High testing range

- Compression plates for proper placement of the test specimen.

- Compression nut provided with the machine to adjust the alignment of the compression plate.

- Micro-controller based peak load indicator for accurate readout and storage of test results.

- Limit switches protection for protection of grips and the machine.

- Powder coated body with corrosion resistance finish.

- Data can be tabulated in Excel

- Report has description of Product name , Operator , Batch , Shape , Standard ,Date , Time & Remarks

- Strong base plate with rugged structure.

- Feather touch controls

- 10 Sample test reports can be seen on one report

- Report Available in PDF format

- Easy Data Management. The user can create product identification, test details, etc.

Technical specifications

- Platform Size: 600 mm X 600 mm 1000 mm X 1000 mm

- Maximum Load range: 500 kgf and 1000 kgf

- Test Speed Range: 10 ± 2 mm/min

- Home position return Speed : 50 mm/min ± 10%

- Load Monitoring: Peak Load indicator with digital readout and peak hold feature

- Load Sensor: S-type Load Cell.

- Load accuracy: ±3% full scale (with master load.)

- Deflection: ±3% full scale

- Least count: 500 kgf- 200gm and 1000 kgf- 1 kgf

- Load Cell Over load safety: <80% of total load.

- Motor Power: 1 HP and 2 HP

- Motor Speed: 1350 RPM three phase motor.

- Safety Feature: Upward and downward fixed and movable limit switches

- Over Load relay contact rating: Potential free relay 5 Amp. 220 V AC single phase

- Main supply: 220 V AC single phase 50 Hz

- Earthing Required: Proper Earthing required corresponding not more than 4 V AC with respect to neutral