Scuff Resistance Tester - NXG

4.9 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

Testing f..read more

Features of Scuff Resistance Tester - NXG

This testing machine from Presto has been equipped with different set of features. PRESTO® undertakes that all the instruments marketed by them are manufactured by them at their works and /or through their approved vendors and sold after a thorough inspection by a team of experts in quality control and assurance departments. Here we have created a list of them below.

- Easy to operate and install

- Reduce printing error by effective testing

- Highly accurate testing results of printing quality

- It has been pre-set with a large number of strokes (typically 100 cycles)

- Machine can be started as per customer specifications

- Sample can be tested within short span of time

- Consist of HMI display for accurate reading of test.

Technical specifications

- Model Type: Mini Bench Model

- Test Weight: 2psi (Customized as per Requirement)

- Rubbing: Uni -Directional @60rpm both upper jaw and lower jaw

- Counter: 6 -digit Digital Preset type with LCD Display

- Digital Counter Range: 0- 999999 Counts

- Diameter of Upper Clamp: 48mm ± 2mm

- Diameter of Lower Clamp: 120mm ± 2mm

- Upper Motor Capacity: 20 kg/cm2 Torque/ 220VAC Single Phase

- Lower Motor Capacity: 6 Watt

- Rotation of Upper Clamp: clockwise @60 rpm

- Rotation of Lower Clamp: Clockwise @60 rpm

- Safety Lock: Provided with Upper Clamp

- Mode of Operation: Motorised

- Input Voltage: 5 Amp. 220 V AC, Single Phase, 50 Hz + Earth

- Sample Preparation Templates: 3 Nos. (50, 100, 200)

- Standard: ASTM F 2497-05, BS 3110:1959

Related Products

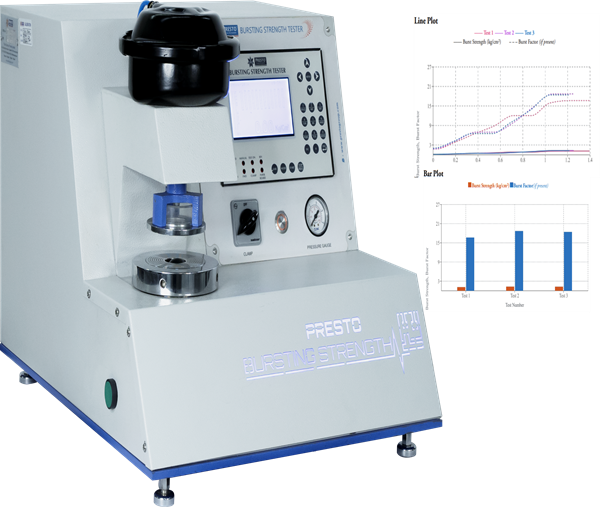

Bursting Strength Tester – Genie Smart 3.0

TP310 Precision Color Matching

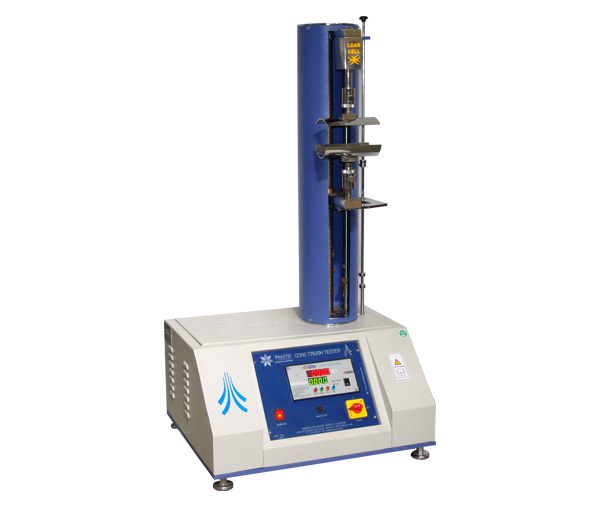

RCT/FCT/Edge Crush Tester

Hot Air Oven – Digital Model

For More details & Information

Please fill this form

Scuff Resistance Tester - NXG

4.9 out of 5

Availability: In Stock

Shipping location: All over the world

Brand: Testing Instruments

Testing for scuff resistance is an important step in the production process. Scuffs and scratches can happen during the shipping, handling, and storage of products. To ensure that your packaging will withstand the test of time, it's best to take steps early in the design process with a Scuff Resistance Test (SRT). SRTs are conducted by applying pressure using a hand-held instrument with a specially designed tip until there is no more adhesive left between two layers of material. Presto Scuff Tester NXG model is one of the best testing instruments that help you to evaluate the Print Quality / Rub proof ness of prints on a substrate. If you want to achieve good quality prints then you need to use good ink and good paper along with the appropriate ink drying machines. The packaging industry is constantly evolving. The latest trend in the market is to produce items with a scuff-resistant coating, which can help reduce product damage and make it easier for customers to use them without getting frustrated. If you want your products to be successful in today’s competitive world, it’s important that they stand up with quality prints.

With the use of the Presto Scuff resistance tester NXG model, you can easily check the color transfer when one surface is rubbed against the other when subjected to continuous rubbing under a specified load. PRESTO Scuff Resistance Tester is designed as per standards ASTM F2497-05, BS 3110:1959.

If you work in the paper and packaging industry, your products will inevitably come with printed information on them. These prints will get damaged if they are rubbed harshly enough. To test how well an object withstands scratches or rubs before shipping out for delivery use Presto Testing Instruments scuff tester. It will give us assurance about quality control throughout our supply chain. This testing instrument is one of the best testing equipment that will help you evaluate the rub proof ness of prints.

The sample is attached to the base of the tester with the printed side up. A 2 psi test weight is attached to the sample and placed in position over the sample so that the printed sides are face to face. (Ensure use of customer specified material in place of the sample where required by customer). The tester is pre-set for the number of strokes (typically 100 cycles) and the machine is started as per the customer specification. After the required number of strokes, the samples are examined for any signs of ink transfer or scuffing. With its easy-to-install and maintenance features, you will be able to test the quality of prints.

The control panel of this testing machine consist of test start and stop button with UP, down and reset key. You can take this test for scuffing or smudge testing for the inks in the paper and packaging industry. If you want to test the specimen for checking the quality of printing ink then you should take a piece of the sample you want to test. Now, you can take the smaller size of the template i.e. 48mm, and cut it accordingly. In the same way, you can prepare the sample for the upper clamp and place it firmly using a sample grip.

To perform this test, you should turn on the machine and clamping both the samples firmly on the device, pull down the level pin so that both the Samples of the upper and lower clamp touch each other. Now Set the number of cycles, press set wait for 2 seconds, then the screen will show program mode wait for 2 seconds then counts screen will appear, set the counts with the help of up/down and reset key (used for shifting) i.e. between 0 – 999999 counts (As per test requirement). Now put the weight of 2psi on the machine which is provided with the device. Push the start button to start the test. You can also click on the reset button during the test to reset the test procedure and then again the start button. For resetting no. of counts on the home screen, make use of the reset key then start key. Once the test gets completed, then you should remove the weight from the device. In this way, you can easily test the sample and evaluate the result.

Features of Scuff Resistance Tester - NXG

This testing machine from Presto has been equipped with different set of features. PRESTO® undertakes that all the instruments marketed by them are manufactured by them at their works and /or through their approved vendors and sold after a thorough inspection by a team of experts in quality control and assurance departments. Here we have created a list of them below.

- Easy to operate and install

- Reduce printing error by effective testing

- Highly accurate testing results of printing quality

- It has been pre-set with a large number of strokes (typically 100 cycles)

- Machine can be started as per customer specifications

- Sample can be tested within short span of time

- Consist of HMI display for accurate reading of test.

Technical specifications

- Model Type: Mini Bench Model

- Test Weight: 2psi (Customized as per Requirement)

- Rubbing: Uni -Directional @60rpm both upper jaw and lower jaw

- Counter: 6 -digit Digital Preset type with LCD Display

- Digital Counter Range: 0- 999999 Counts

- Diameter of Upper Clamp: 48mm ± 2mm

- Diameter of Lower Clamp: 120mm ± 2mm

- Upper Motor Capacity: 20 kg/cm2 Torque/ 220VAC Single Phase

- Lower Motor Capacity: 6 Watt

- Rotation of Upper Clamp: clockwise @60 rpm

- Rotation of Lower Clamp: Clockwise @60 rpm

- Safety Lock: Provided with Upper Clamp

- Mode of Operation: Motorised

- Input Voltage: 5 Amp. 220 V AC, Single Phase, 50 Hz + Earth

- Sample Preparation Templates: 3 Nos. (50, 100, 200)

- Standard: ASTM F 2497-05, BS 3110:1959