Torque Tester HMI Motorized

4.67 out of 5

If you are looking for accurate testing equipment for measuring the torque value of opening the bottle caps, then we suggest you go with the Presto torque tester digital motorized model. Torque Tester – Digital Motorized is a new generation fully automatic motoriz..read more

This torque tester comes with a digital monitor setting that makes it easy for you to conduct the test. If you wish to operate this testing equipment then you can plug the main switch into 3 Pin - 5 Amp. Power supply socket. Turn the main switch on. After that, you can easily place the specimen by following the steps given below.

- Rotate the jaw adjusting knob in the anticlockwise direction to take the jaws apart.

- Place the sample of the bottle to be tested on the test platform.

- Adjust the specimen holding pegs according to the size of the specimen.

- Place the specimen properly in such a way that it is perfectly straight and touches all four pegs at a given time.

- After placing the specimen, tighten the jaw adjusting knob properly by revolving it in a clockwise direction.

- Place the upper closure on the bottle sample and adjust it according to the height of the sample and tighten the knob appropriately.

- The Load indicator might show some readings due to previous test values.

With these given steps, you can easily place the specimen accurately. Once the specimen will be placed accurately, then you can set the torque value to zero. Press the TARE button and then press RESET. The load indicator will show a zero reading. Once you follow all the above-mentioned steps, you can easily commence the test. If you find any difficulty in commencing the test, then you can easily consult with us.

Features of Torque Tester HMI Motorized

- An auto-stop feature once it reaches the angle of 60 Degree.

- The testing machines automatically get restored to the starting position after testing.

- The device is also incorporated with the inbuilt calibration mechanism.

- It also offers easy clamps to clamp the specimen easily to perform the test.

- The instrument is duly fitted with a digital display to read the test results easily.

- It is an ideal testing machine that is mandatory for rotating

- The testing device is best for the following applications like Aerospace, Screw Closures, Child Resistance Components, Bottle Torque Testing, and Automotive Components.

- Strong clamping pegs/holders for zero slip gripping support

- Digital Display for accuracy and repeatability

- Precise measurement of torque

- Height adjustable clamping mechanism to hold the different size of bottles

- 9 Sample readings can be seen on the digital readout

- Auto Stop Function enabled

- Motorized feature for high repeatability

- Data output in digital display form

- Servomotor Driven Mechanism

- Adjustable fixture to test different size test bottles

Technical specifications

- The maximum size of the sample is 400mm and the Minimum size of the sample is100mm respectively.

- The test result display of the device is a digital load indicating the unit.

- Load indicator display resolution of the machine is 01 LB. – IN.

- The peak Hold feature of the device displays peak hold storage for the first nine peak values

- The measuring sensor of the machine is of torque transducer load cell.

- The maximum range displayed by the device is 80 LB. –IN

- The specimen rotates to the angle of 60 degrees and automatically stops and automatic restored to its initial position

- The instrument offers the accuracy of +/-1% of Full Scale

- The least count of the device is 0.1 LB. – IN

- The instrument has a servo motor drive rotatory mechanism

- It supports In-Built calibration mechanism fixtures.

- Torque zero balance – +/-1.0% FSO

- Power: 220V, Single phase, 50 Hz

- Display: Digital

- Max. size of test bottles to be tested: 2.5 liters

- Weights for Calibration: 10 lbs, 20 lbs

- Safety: Yes

- Standard weights (for calibration): 2

- Specimen rotation: Automatic restoration to initial position

Related Products

Drop Tester

Polariscope Strain Viewer for Glass

Vacuum Leak Tester – PRIMA SERIES

Flip Cap Opening Tester

For More details & Information

Please fill this form

Related Products

Top Load Tester – Digital

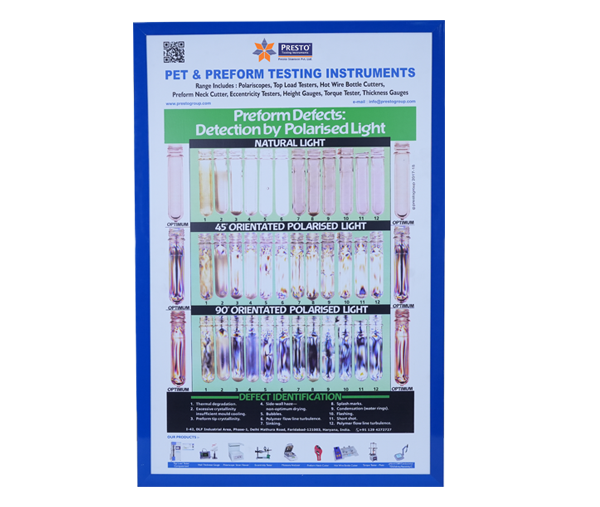

Preform Defect Chart

Fill Height Gauge

Dead Weight Tester

Torque Tester HMI Motorized

4.67 out of 5

If you are looking for accurate testing equipment for measuring the torque value of opening the bottle caps, then we suggest you go with the Presto torque tester digital motorized model. Torque Tester – Digital Motorized is a new generation fully automatic motorized torque tester. It gives Torque in digital format. The digital display is a sophisticated high-end read-out with Auto Tare (ZERO) set facility and Peak Hold arrangement. The test sample is placed in between the anti-slip holders/pegs for the strong holding of the test sample.

A Motorized Torque tester is a sophisticated device that is designed to provide the accurate analysis of the force or torque needed to open a closed cap of a PET bottle. The instrument is highly useful in studying the efficiency of bottle caps in the PET industries. As most of the products that are packaged in PET bottles are mainly in liquid form, they can easily be spilled over if the cap of the bottles is not closed properly. At the same time, it is also important to make sure that the bottle cap is not closed so tightly that it becomes difficult to open the bottles. The Torque tester enables the manufacturers to ensure that the bottle caps are tightened with optimum force and are opened easily.

The main purpose of using this lab testing equipment is to ideally determine the strength required to open the cap of a PET bottle and ensure that the bottle is safe for use. This testing instrument will be widely used in the PET bottle manufacturing industry. The equipment is provided with a highly accurate torque sensor that records the torque applied on the test specimen with great accuracy. The operation of the machine is manual whereas the torque determination is done with the help of a digital display readout. A safety lock pin is provided with the machine that prevents the rotating of the clamping device so that there is no unnecessary torque applied on the torque sensor.

Presto manufactures the best quality of Torque Tester to examine the quality of the Torque of the Bottle Caps. The testing device is widely used in PET Bottle Industry and pharmaceutical industries. It is the motorized model which provides the result in digital format. This testing instrument is also known as Pluto Series. The testing machine is used in pharmaceutical and PET laboratories to test the quality of the torque of the PET bottles. The instrument provides the facility of Auto-stop function when it touches an angle of 60 Degree. The testing machine automatically gets restored to its initial position after the testing is done. The device is also incorporated with the integral calibration mechanism. It provides easy clamping to clamp the test sample easily to perform the test. The testing machine is fitted with an extremely accurate digital display that helps to read the testing results easily. It is the best testing machine that is necessary for the rotating components. Torque Tester is designed to provide accurate and precision-based torque value which is not otherwise obtained by manual twisting. The instrument is used for testing the opening force of the PET bottles when subject to a load under twisting.

This torque tester comes with a digital monitor setting that makes it easy for you to conduct the test. If you wish to operate this testing equipment then you can plug the main switch into 3 Pin - 5 Amp. Power supply socket. Turn the main switch on. After that, you can easily place the specimen by following the steps given below.

- Rotate the jaw adjusting knob in the anticlockwise direction to take the jaws apart.

- Place the sample of the bottle to be tested on the test platform.

- Adjust the specimen holding pegs according to the size of the specimen.

- Place the specimen properly in such a way that it is perfectly straight and touches all four pegs at a given time.

- After placing the specimen, tighten the jaw adjusting knob properly by revolving it in a clockwise direction.

- Place the upper closure on the bottle sample and adjust it according to the height of the sample and tighten the knob appropriately.

- The Load indicator might show some readings due to previous test values.

With these given steps, you can easily place the specimen accurately. Once the specimen will be placed accurately, then you can set the torque value to zero. Press the TARE button and then press RESET. The load indicator will show a zero reading. Once you follow all the above-mentioned steps, you can easily commence the test. If you find any difficulty in commencing the test, then you can easily consult with us.

Features of Torque Tester HMI Motorized

- An auto-stop feature once it reaches the angle of 60 Degree.

- The testing machines automatically get restored to the starting position after testing.

- The device is also incorporated with the inbuilt calibration mechanism.

- It also offers easy clamps to clamp the specimen easily to perform the test.

- The instrument is duly fitted with a digital display to read the test results easily.

- It is an ideal testing machine that is mandatory for rotating

- The testing device is best for the following applications like Aerospace, Screw Closures, Child Resistance Components, Bottle Torque Testing, and Automotive Components.

- Strong clamping pegs/holders for zero slip gripping support

- Digital Display for accuracy and repeatability

- Precise measurement of torque

- Height adjustable clamping mechanism to hold the different size of bottles

- 9 Sample readings can be seen on the digital readout

- Auto Stop Function enabled

- Motorized feature for high repeatability

- Data output in digital display form

- Servomotor Driven Mechanism

- Adjustable fixture to test different size test bottles

Technical specifications

- The maximum size of the sample is 400mm and the Minimum size of the sample is100mm respectively.

- The test result display of the device is a digital load indicating the unit.

- Load indicator display resolution of the machine is 01 LB. – IN.

- The peak Hold feature of the device displays peak hold storage for the first nine peak values

- The measuring sensor of the machine is of torque transducer load cell.

- The maximum range displayed by the device is 80 LB. –IN

- The specimen rotates to the angle of 60 degrees and automatically stops and automatic restored to its initial position

- The instrument offers the accuracy of +/-1% of Full Scale

- The least count of the device is 0.1 LB. – IN

- The instrument has a servo motor drive rotatory mechanism

- It supports In-Built calibration mechanism fixtures.

- Torque zero balance – +/-1.0% FSO

- Power: 220V, Single phase, 50 Hz

- Display: Digital

- Max. size of test bottles to be tested: 2.5 liters

- Weights for Calibration: 10 lbs, 20 lbs

- Safety: Yes

- Standard weights (for calibration): 2

- Specimen rotation: Automatic restoration to initial position