Secure Seal Tester for Glass Bottles

4.9 out of 5

The seal integrity of glass bottles plays an important role in determining whether the package will be safe and secure to be delivered to the customers. Seal integrity testing will also help the manufacturers to ensure that there is no sign of any structural weakness pr..read more

Features of Secure Seal Tester for Glass Bottles

• HMI-based Touchscreen Model

• Microprocessor-based controls

• Automatic sample testing through an easy pressure release mechanism

• Pressure, Inlet Pressure setting, and Preset Timer functions incorporated in HMI

for accuracy and repeatability

• Pressure Vs Time live graph

• Program profile for selecting test parameters and performing the test.

• Easy Data Management. Users can create product identification, test pressure, time, etc.

• USB option available for storing test data

• Data output in excel format.

• Current test running status display

• Changeable Pressure Units

• Inbuilt Calibration facility

• 2-layer safety container

Technical specifications

-

Display: HMI Based on a touchscreen

-

Equipment Range: 220 psi

-

Test Range: 175 psi

-

Accuracy: ±2% at full range

-

Least Count/Resolution: 0.1 psi

-

Power: 220V, Single phase, 50 Hz

-

Pressure Unit: Inbuilt in HMI (changeable in Kg/cm² psi& bar

-

Inner Size of testing container: L 250 x W 225 X H 450 mm

-

Timer: Inbuilt in HMI Preset up to 999 seconds

-

Pressure Release: Auto pressure release system

-

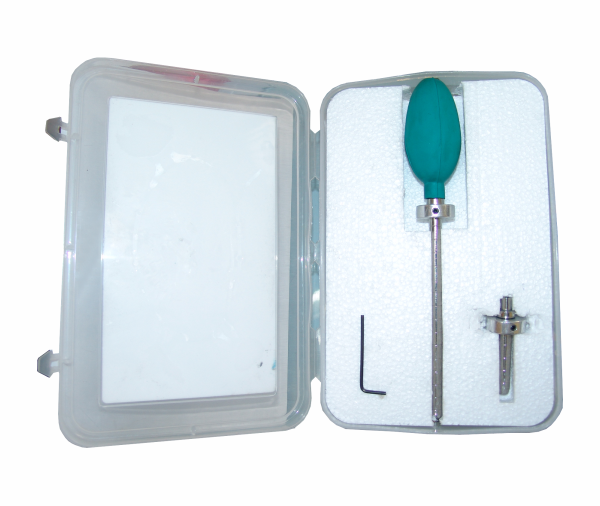

Sample Holder: Piercing fixture for crown cap

Related Products

Color Matching Cabinet Spectrum – I (ASIA)

Bottle Burst Tester - Touchscreen

Auto Clave

TP310 Precision Color Matching

For More details & Information

Please fill this form

Secure Seal Tester for Glass Bottles

4.9 out of 5

The seal integrity of glass bottles plays an important role in determining whether the package will be safe and secure to be delivered to the customers. Seal integrity testing will also help the manufacturers to ensure that there is no sign of any structural weakness present in the bottles that will lead to damage to the contents during transit and rough handling.

Thus, to ensure that your glass bottles are properly sealed, we at Presto have designed high-quality lab testing equipment known as a secure seal tester for Glass bottles. This testing equipment has been designed with HMI based touchscreen display and can test the bottles with a range of 220 psi.

Users will get changeable pressure units with easy data management and can create product identifications, test pressure, time, etc. USB option will also be available for storing the data and this machine will also display different lab testing results.

This secure seal lab testing instrument is highly useful in determining the strength of glass bottles against leakage. Below we have listed the features of this high-quality lab testing equipment.

Features of Secure Seal Tester for Glass Bottles

• HMI-based Touchscreen Model

• Microprocessor-based controls

• Automatic sample testing through an easy pressure release mechanism

• Pressure, Inlet Pressure setting, and Preset Timer functions incorporated in HMI

for accuracy and repeatability

• Pressure Vs Time live graph

• Program profile for selecting test parameters and performing the test.

• Easy Data Management. Users can create product identification, test pressure, time, etc.

• USB option available for storing test data

• Data output in excel format.

• Current test running status display

• Changeable Pressure Units

• Inbuilt Calibration facility

• 2-layer safety container

Technical specifications

-

Display: HMI Based on a touchscreen

-

Equipment Range: 220 psi

-

Test Range: 175 psi

-

Accuracy: ±2% at full range

-

Least Count/Resolution: 0.1 psi

-

Power: 220V, Single phase, 50 Hz

-

Pressure Unit: Inbuilt in HMI (changeable in Kg/cm² psi& bar

-

Inner Size of testing container: L 250 x W 225 X H 450 mm

-

Timer: Inbuilt in HMI Preset up to 999 seconds

-

Pressure Release: Auto pressure release system

-

Sample Holder: Piercing fixture for crown cap