Salt Spray Chamber for Corrosion Testing - Korrox III

5 out of 5

Presto salt spray chamber touch screen (1000 Ltr) testing instrument is designed for you if you want to know whether your product can withstand corrosion. The Salt Spray Chamber is a tim..read more

Salt Spray Chamber : Working Principle and Operation

This time-tested instrument is the perfect solution for testing the corrosion resistance of components. It’s a time-tested product that has been specifically designed to assess the rust-proof ability of components to withstand corrosion due to atmospheric conditions. With this chamber, you can simulate real-life weathering conditions and ensure your products will stand up against them. This chamber provides complete flexibility in the simulation of real-life weathering conditions so you can test out all kinds of different scenarios with ease. Now, let us focus on the steps for the working of this testing instrument.

- Turn this machine ON by plugging it into the main socket. You should ensure to follow all safety measures.

- Rotate the “Main Switch” Knob from the Control Panel. Open the Electric Circuit Panel and check whether all the MCB’s are “ON”.

- After checking all the required conditions, you should make sure to fill the air saturator with a DM solution.

- You should prepare the salt solution to fill the reservoir tank. You can do this by dissolving 5±1% parts by weight of sodium chloride in 95% parts of distilled water or water containing not more than 200ppm of total solids.

- The salt used can be sodium chloride substantially free of nickel and copper-containing on a dry basis, not more than 0.1% of sodium iodide and not more than 0.3% of total impurities. After you prepare the salt solution, then you should filter it before placing it in the reservoir.

- Now open the cover of the Reservoir Tank just below the Air Pressure Control Panel and fill the solution manually using a beaker.

- You can also fill the reservoir tank using an external solution tank of minimum height (Under Customer’s Scope). For this, connect the M8 PU Pipe with the Salt Solution Inlet Port and fill the salt solution.

- Prepare the specimen by cleaning them effectively. After that, you can place them in the chamber and make sure that the specimen should not contact each other.

In this way, you can easily conduct the salt spray test and check the durability of your products. This chamber will give you peace of mind knowing that whatever comes at it – it can handle it with ease. Don’t wait another minute before signing up for one free trial session today!

Features of Salt Spray Chamber for Corrosion Testing - Korrox III

There are many features you will get with Presto salt spray chamber that we have listed below:

- Easy to install and needs low maintenance.

- Highly accurate testing instrument with the temperature controlling functions.

- Advanced PID controller for effective temperature control.

- Touch screen control panel embedded with advanced features.

- 7″ TFT LCD color screen

- Supports CF memory card

- 3M Flash Memory

- 3 sets of COM ports for multiple

- 8 function keys

Technical specifications

- Chamber Temperature Ambient to 350 C.

- Air Saturator Temperature 40oC to 49 o C.

- Fog Collection Funnel 10 cm Diameter & 80 cm2 Area

- pH Value of Salt Solution: 6.5 to 7.2

- Test Air Pressure: 0.7kg/cm2 -1.2kg/cm2

- Mass of Salt Addition 5% of Salt Addition

- Outer Body Material: Fiber Glass

- Chamber Temperature Least Count: 0.1 0 C

- Chamber Temperature Repeatability : ±20 C

- Air Saturator Temperature Least Count: 0.10 C

- Air Saturator Temperature Repeatability: ±20 C

- Mode of Operation: HMI Interface

- Electrical supply: 15 Amp. 230 V AC, Single Phase, 50 Hz + Earth

- Power consumption: 4.2 KW

Related Products

Bench UV Light Accelerated Weathering Tester (Touch Screen)

Hot Air Oven – Touch Screen

UV Light Accelerated Weathering Tester - Touch Screen

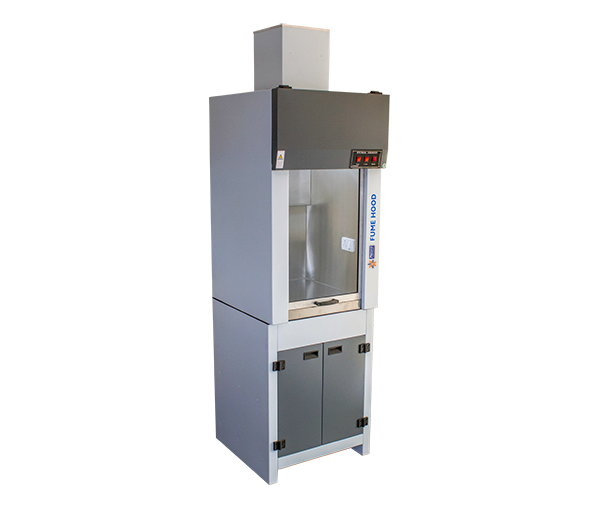

Fume Hood

For More details & Information

Please fill this form

Salt Spray Chamber for Corrosion Testing - Korrox III

5 out of 5

Presto salt spray chamber touch screen (1000 Ltr) testing instrument is designed for you if you want to know whether your product can withstand corrosion. The Salt Spray Chamber is a time-tested product that has been specifically designed to assess the rust-proof ability of components. It provides complete flexibility in the simulation of real-life weathering conditions. With this chamber, you can test how well your products will hold up against corrosion from saltwater and other atmospheric conditions. You won’t have any more guesswork when it comes to testing the durability of your products – let us take care of all the work for you. You can use this chamber for corrosion testing on any kind of metal or alloy, including aluminum alloys and steel. This chamber simulates the corrosive effects of salt spray fog at a temperature range from Ambient to 350 C. With this chamber, you can test your products under realistic environmental conditions without having to expose them directly to the elements.

In the metal industry, corrosion is the most important property of metals that needed to be tested accurately. It can destroy the product if not tested at the right time. Thus, with Presto Salt Spray Chamber, you must ensure that you are delivering tested products to your customers. To maintain the durability of metal products, it is very important for you to make them rust-free. That’s why we love helping people stay focused on their businesses as they grow by providing them with the best corrosion testing equipment available. You won't have to worry about ever picking up that phone call from your customer that isn't happy with how rusty their product is. Never stress over corroded products, missing shipments, and the mess of corrosion testing. With the help of a salt spray chamber, you can easily take care of all your corrosion needs. Our salt spray tester is specially designed with high-quality material with complete flexibility in the simulation of real-life weathering conditions. With our salt spray chamber, you can test your products under any condition and ensure they are completely protected against corrosion from all angles. You won’t have to worry about having rusty equipment or losing money because your customers aren’t satisfied with their purchases anymore. It’s the ideal testing tool for manufacturers who need to assess how well their products hold up against corrosion from salt spray or other environmental factors. With this product, you'll know exactly what kind of performance your equipment is.

This testing material has the outer body material that is made of fiberglass. The chamber can easily be operated with an HMI interface and provide information about your product whether it can withstand high temperature and different environmental conditions or not. Thus, this testing instrument will also help you in determining the performance of the specimen. This time-tested product has been specifically designed to assess the rust-proof ability of components to withstand corrosion due to atmospheric conditions. It provides complete flexibility in the simulation of real-life weathering conditions. The device is used in industrial testing laboratories for various research and analysis purposes. The instrument is capable of creating very high temperatures for testing and studying the effect on different painted and plated metal substrates. The touch screen installed in the Salt Spray Tester is a powerful tool that eases the analysis of corrosion resistance for a wide variety of sample types. A special zero corrosion PT 100 sensor is incorporated in the touch screen. It also has 8 function keys, a 3M flash memory, and provides a USB host for a USB flash drive. The test specimens can be continuously exposed to the appropriate salt spray volume. The ergonomic position of the touch screen ensures ease of use.

Salt Spray Chamber : Working Principle and Operation

This time-tested instrument is the perfect solution for testing the corrosion resistance of components. It’s a time-tested product that has been specifically designed to assess the rust-proof ability of components to withstand corrosion due to atmospheric conditions. With this chamber, you can simulate real-life weathering conditions and ensure your products will stand up against them. This chamber provides complete flexibility in the simulation of real-life weathering conditions so you can test out all kinds of different scenarios with ease. Now, let us focus on the steps for the working of this testing instrument.

- Turn this machine ON by plugging it into the main socket. You should ensure to follow all safety measures.

- Rotate the “Main Switch” Knob from the Control Panel. Open the Electric Circuit Panel and check whether all the MCB’s are “ON”.

- After checking all the required conditions, you should make sure to fill the air saturator with a DM solution.

- You should prepare the salt solution to fill the reservoir tank. You can do this by dissolving 5±1% parts by weight of sodium chloride in 95% parts of distilled water or water containing not more than 200ppm of total solids.

- The salt used can be sodium chloride substantially free of nickel and copper-containing on a dry basis, not more than 0.1% of sodium iodide and not more than 0.3% of total impurities. After you prepare the salt solution, then you should filter it before placing it in the reservoir.

- Now open the cover of the Reservoir Tank just below the Air Pressure Control Panel and fill the solution manually using a beaker.

- You can also fill the reservoir tank using an external solution tank of minimum height (Under Customer’s Scope). For this, connect the M8 PU Pipe with the Salt Solution Inlet Port and fill the salt solution.

- Prepare the specimen by cleaning them effectively. After that, you can place them in the chamber and make sure that the specimen should not contact each other.

In this way, you can easily conduct the salt spray test and check the durability of your products. This chamber will give you peace of mind knowing that whatever comes at it – it can handle it with ease. Don’t wait another minute before signing up for one free trial session today!

Features of Salt Spray Chamber for Corrosion Testing - Korrox III

There are many features you will get with Presto salt spray chamber that we have listed below:

- Easy to install and needs low maintenance.

- Highly accurate testing instrument with the temperature controlling functions.

- Advanced PID controller for effective temperature control.

- Touch screen control panel embedded with advanced features.

- 7″ TFT LCD color screen

- Supports CF memory card

- 3M Flash Memory

- 3 sets of COM ports for multiple

- 8 function keys

Technical specifications

- Chamber Temperature Ambient to 350 C.

- Air Saturator Temperature 40oC to 49 o C.

- Fog Collection Funnel 10 cm Diameter & 80 cm2 Area

- pH Value of Salt Solution: 6.5 to 7.2

- Test Air Pressure: 0.7kg/cm2 -1.2kg/cm2

- Mass of Salt Addition 5% of Salt Addition

- Outer Body Material: Fiber Glass

- Chamber Temperature Least Count: 0.1 0 C

- Chamber Temperature Repeatability : ±20 C

- Air Saturator Temperature Least Count: 0.10 C

- Air Saturator Temperature Repeatability: ±20 C

- Mode of Operation: HMI Interface

- Electrical supply: 15 Amp. 230 V AC, Single Phase, 50 Hz + Earth

- Power consumption: 4.2 KW