Melt Flow Index Junior

4.9 out of 5

The melt flow rate (MFR) of a polymer is one of its most important properties. It is a measure of the ease with which the polymer can be melted and processed. A high MFR indicates that the polymer can be easily melted and processed, while a low MFR indicates that the po..read more

Features of Melt Flow Index Junior

Melt flow rate is an essential property to consider when selecting a polymer for your application. This is because the melt flow rate indicates how easy the material is to process. It has been equipped with a high set of features that makes it easy for manufacturers to conduct melt flow tests on the materials. Below we have listed the features of this quality testing equipment.

-

Automatic sample cutting

-

Microprocessor-based PID controller

-

Digital Preset Timer for accuracy and repeatability

-

Die Steel barrel for uniform and the consistent heating of barrel/test cylinder.

-

Heater enable and disable separate button

-

Wide mirror platform easy to monitor the flow.

-

Compact and stable structure

Technical specifications

-

Temperature Range: Ambient to 350 ºC

-

Display: Digital 7 Segment

-

Accuracy: ± 1ºC

-

Least Count/Resolution: 0.1ºC

-

Power: 220V, Single phase, 50 Hz

-

Sample Cutting: Automatic Motorized

-

Temperature Control: PID Temperature Controller

-

Timer: Digital Preset up to 999 seconds

-

Inner Diameter of the heating barrel (cylinder): 9.550mm ± 0.007mm

-

Inner Diameter of Die: 2.095mm ± 0.005mm

-

Diameter of piston head: 9.474mm ± 0.007mm

-

Material of Heating Barrel(Cylinder): Die Steel

-

Sample Cutting Motor: 2 Torque 7Kg/cm, 60RPM

Highlights:

-

No. of Dead Weights: 4 (1.2 kg, 2.16 kg, 3.8 kg, 5 kg)

-

Material: Mild Steel

-

Finish: Powder-coated Havel Gray & Blue combination finish and bright chrome/zinc plating for a corrosion-resistant finish

-

Dimensions: 300x644x642 mm

Related Products

Tearing Strength Tester- Model No. PTT-560 Prima

Humidity/Conditioning Test Chambers Deluxe Model

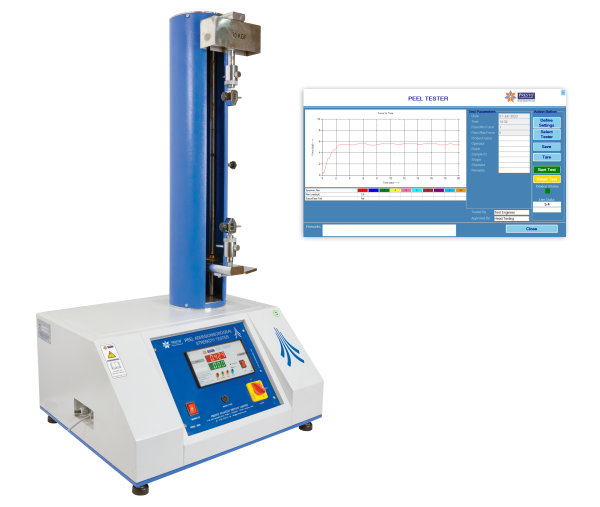

Peel Seal Bond and Adhesion Tester Digital cum Computerised Model

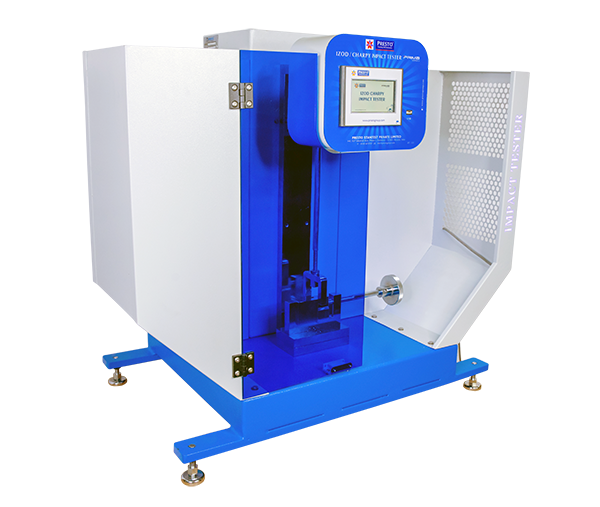

IZOD/Charpy Impact Tester NXG

For More details & Information

Please fill this form

Melt Flow Index Junior

4.9 out of 5

The melt flow rate (MFR) of a polymer is one of its most important properties. It is a measure of the ease with which the polymer can be melted and processed. A high MFR indicates that the polymer can be easily melted and processed, while a low MFR indicates that the polymer will be more difficult to melt and process.

Presto Melt Flow Index Junior is one of the high-quality lab testing equipment that is used to test the different properties of the materials and ensure that quality products will be delivered to the customers.

A digital weighing balance has been equipped in the melt flow index tester junior model that can measure the weight of the sample with great accuracy. The automatic cutting of samples is one of the highly useful features as it will save time and effort in cutting the samples for testing.

This quality lab testing equipment has been designed as per industrial standards that include ASTM D 1238-1992, IS 2267-1972, IS 2530-1963, and IS 10810-1984. Manufacturers of the polymer testing industry can easily make use of this quality testing equipment and ensure that accurate testing results will be provided to the customers.

Features of Melt Flow Index Junior

Melt flow rate is an essential property to consider when selecting a polymer for your application. This is because the melt flow rate indicates how easy the material is to process. It has been equipped with a high set of features that makes it easy for manufacturers to conduct melt flow tests on the materials. Below we have listed the features of this quality testing equipment.

-

Automatic sample cutting

-

Microprocessor-based PID controller

-

Digital Preset Timer for accuracy and repeatability

-

Die Steel barrel for uniform and the consistent heating of barrel/test cylinder.

-

Heater enable and disable separate button

-

Wide mirror platform easy to monitor the flow.

-

Compact and stable structure

Technical specifications

-

Temperature Range: Ambient to 350 ºC

-

Display: Digital 7 Segment

-

Accuracy: ± 1ºC

-

Least Count/Resolution: 0.1ºC

-

Power: 220V, Single phase, 50 Hz

-

Sample Cutting: Automatic Motorized

-

Temperature Control: PID Temperature Controller

-

Timer: Digital Preset up to 999 seconds

-

Inner Diameter of the heating barrel (cylinder): 9.550mm ± 0.007mm

-

Inner Diameter of Die: 2.095mm ± 0.005mm

-

Diameter of piston head: 9.474mm ± 0.007mm

-

Material of Heating Barrel(Cylinder): Die Steel

-

Sample Cutting Motor: 2 Torque 7Kg/cm, 60RPM

Highlights:

-

No. of Dead Weights: 4 (1.2 kg, 2.16 kg, 3.8 kg, 5 kg)

-

Material: Mild Steel

-

Finish: Powder-coated Havel Gray & Blue combination finish and bright chrome/zinc plating for a corrosion-resistant finish

-

Dimensions: 300x644x642 mm