Core Compression Tester Motorized

4.9 out of 5

Paper cores are an essential component of the paper and packaging industry. They are used to roll and store a variety of products such as papers, films, tapes, foils, labels, and fabrics. Testing the quality of these paper cores is an essential part of the quality control process. Thus, we at Pre..read more

Features of Core Compression Tester Motorized

-

Inbuilt calibration facility

-

Motorized system (Maintenance free)

-

Overload facility

-

Microprocessor-based display for accurate test results

-

Highly accurate test results under uniform compression Force

-

TARE and Peak Hold Facility Available

-

Strong base plate with a rugged structure

-

Feather touch controls

Technical specifications

-

Load cell capacity: 1000 kgf

-

Standard supply fixture of core: 3” & 4” ID

-

Resolution/ least count: 500 g

-

Accuracy: ± 2% full scale (with master load)

-

Test speed: 100 mm/min ± 2%

-

Home speed: 200 mm

-

Dimensions: 1265 x 600 x 1325 mm

-

Mechanism: Motorized

-

Power Requirement: 220V, 50/60 Hz, 5 Amp

* Another fixture supply on request up to 12” ID (Max 350 mm OD).

* Standard load capacity 1 ton up to 2-ton capacity supply on request.

Related Products

Crush /RCT/ECT /FCT- Digital cum Computerized Model

Crease Stiffness tester

RCT/FCT/Edge Crush Tester

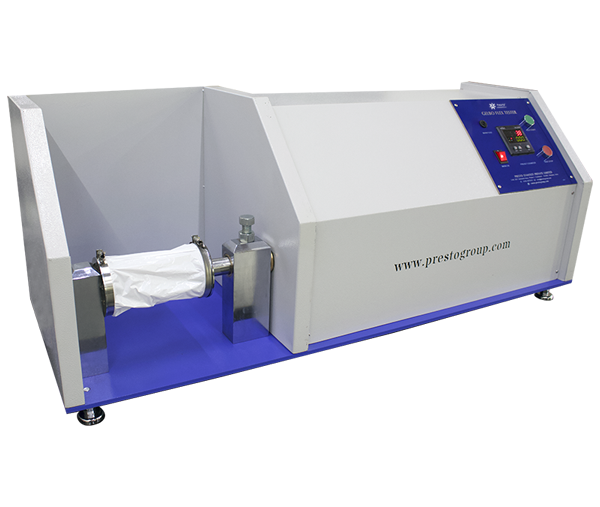

Gelbo Flex Tester

For More details & Information

Please fill this form

Core Compression Tester Motorized

4.9 out of 5

Paper cores are an essential component of the paper and packaging industry. They are used to roll and store a variety of products such as papers, films, tapes, foils, labels, and fabrics. Testing the quality of these paper cores is an essential part of the quality control process. Thus, we at Presto have launched a new lab testing instrument known as Core Compression Tester – Motorized.

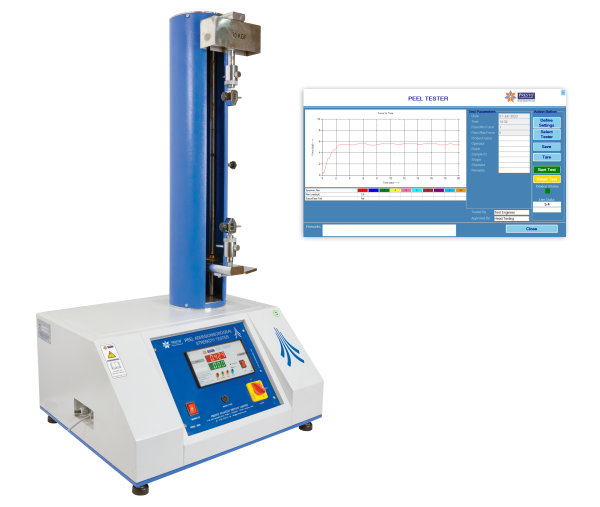

This newly launched Presto Core Compression Tester is a motorized instrument designed to measure the crush or compression resistance of paper cores, commonly used in the paper and packaging industry.

This paper and packaging testing equipment applies a uniform compressive load on a cylindrical paper core of specified length placed between compression plates and records the maximum sustained load value. The collapsing load is determined by placing a cylindrical paper core of specified length in between compression plates (either radial or flat type), applying a uniform magnitude of compressive load on the test specimen, and the maximum sustained load value is then recorded.

Manufactured under the ISO 11093 standard, the Presto Core Compression Tester features an inbuilt calibration facility, a maintenance-free motorized system, and microprocessor-based display for accurate test results, an overload facility, and many other features that make it the unique testing instrument from other brands. This quality core compression testing instrument is designed to provide highly accurate test results under uniform compression force.

Features of Core Compression Tester Motorized

-

Inbuilt calibration facility

-

Motorized system (Maintenance free)

-

Overload facility

-

Microprocessor-based display for accurate test results

-

Highly accurate test results under uniform compression Force

-

TARE and Peak Hold Facility Available

-

Strong base plate with a rugged structure

-

Feather touch controls

Technical specifications

-

Load cell capacity: 1000 kgf

-

Standard supply fixture of core: 3” & 4” ID

-

Resolution/ least count: 500 g

-

Accuracy: ± 2% full scale (with master load)

-

Test speed: 100 mm/min ± 2%

-

Home speed: 200 mm

-

Dimensions: 1265 x 600 x 1325 mm

-

Mechanism: Motorized

-

Power Requirement: 220V, 50/60 Hz, 5 Amp

* Another fixture supply on request up to 12” ID (Max 350 mm OD).

* Standard load capacity 1 ton up to 2-ton capacity supply on request.