Carbon Black Content Apparatus

4.75 out of 5

If you are looking for accurate testing equipment for the determination of the carbon black content in polyethylene, polypropylene, and polybutylene plastics, then we suggest you go with a carbon black content tester. Presto’s carbon black content apparatus is widely used for concluding the..read more

The procedure below assumes that the combustion tube can be easily removed from the furnace. If it is not the case, alternate methods of inserting and removing sample boats are acceptable as long as the temperature, purge time, and flow rate requirements are met.

- Assemble the apparatus. Both cold traps following the combustion tube shall contain trichloroethylene, but only the first need be cooled with solid carbon dioxide.

- Alternatively, the entire apparatus may be placed in a dioxide and in a fume hood and the two traps following the combustion tube are omitted.

- Fill the drying tube with anhydrous CaCl2 or another suitable desiccant. Hold between loose plugs of glass wool.

- Heat a clean combusting boat to red heat in a Bunsen flame then transfer the boat to the desiccator and allow it to cool over fresh desiccant for not less than 30 min.

- Remove the boat from the desiccator and weigh it to the nearest 0.0001 g. immediately place 1. 0 + 0.1 g of the ethylene plastic under teat in the boat and quickly weigh to the nearest 0.0001 g.

- Heat the furnace to a constant temperature of 600 degrees Celsius.

With the combusting tube remove from the furnace adjust the rate of nitrogen flow through the tube to 1.7 + 0.3 L/min. Open the inlet end of the combusting tube, quickly place the combusting boat with the sample into the tube positioned so the boat will be at the proper temperature when in the furnace. Close the inlet to the tube and allow the nitrogen to flow for a minimum of 5 min to purge oxygen from the system prior to placing the tube in the furnace. If the furnace is controlled by an external thermocouple, adjust the thermocouple so that the weld is in proximity to the boat. Insert the copper plug if this is used. Quickly place the tube into the furnace, close the furnace and allow heating to proceed for at least 15 min. Move the tube or furnace so that the boat is no longer in the heated zone of the furnace and allow 5 min for cooling while maintaining the flow of nitrogen. Remove the copper plug, if present, and the boat through the inlet end of the tube and allow it to cool in the desiccator for at least 30 min. Take care that the boat does not tube. Then quickly reweigh the boat and its contents to the nearest 0.0001 g. If carbon black measurements are to be made at values less than 1% then the sample boat with the residue of the tube furnace burn shall be placed in a muffle furnace for approximately 10 min to oxidize the carbon black. This is to correct for the presence of residual inorganic matter in the sample. After heating, cool the sample boat in a desiccator until it is at room temperature. Weigh the boat plus contents to the nearest 0.0001 g. In this way, you can commence the test.

Features of Carbon Black Content Apparatus

- This instrument is supplied with two separate glass flasks.

- The machine is equipped with a programmable P.I.D. temperature

- The machine is incorporated with quartz glass which can resist high temperature.

- The heater of the machine has a relatively low operating voltage that ensures the furnace is long-lasting.

Technical specifications

- The size of the furnace attached to the instrument is 6” x 6”x 6”.

- The temperature range can be set from ambient to 1150°C.

- The inner side of the instrument is made up of Stainless Steel, and the outer side is made up of Mild Steel duly powder coated.

- The laboratory equipment is supplied with some accessories, namely, Glass U Tube, Desiccator, Rubber tube – 1 no., Combustion tube, Combustion boat, Rotometer, Glass traps – 3nos., Glass end caps 2 nos.

- Single-phase power of 230V and 50 Hz.

- Display: Digital LED

- Temp. Range: From ambient to 1150 ° C

- Material of Construction: Inner Brick type and outer mild steel powder-coated

- Accessories: Desiccator, Glass U tube, Combustion tube, Combustion boat, Rotometer, Rubber tube, Glass end caps, Glass traps, Pore clain Boat, Aquartz Tube, Cork Plug

- Power Supply: Single Phase 220-240V AC, 50Hz.

- Control Method: Temp. Controller Digital

- Industry: Polymers/ Rubber/ Plastic

Related Products

Digital Specific Gravity Balance

Gloss Meter – Tri-angle

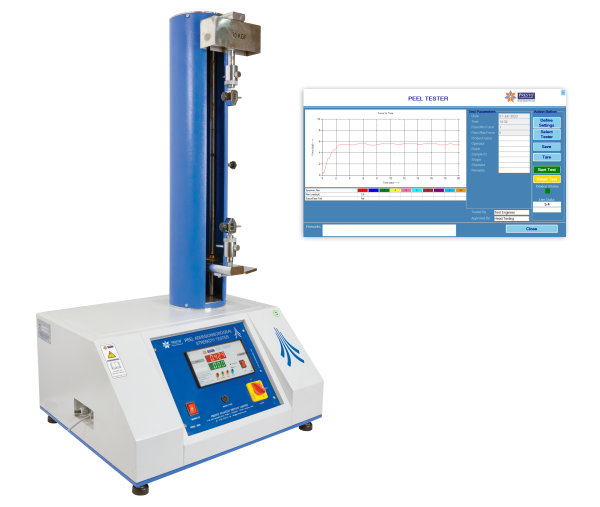

Peel Seal Bond and Adhesion Tester Digital cum Computerised Model

Carbon Black Dispersion Test Apparatus

For More details & Information

Please fill this form

Carbon Black Content Apparatus

4.75 out of 5

If you are looking for accurate testing equipment for the determination of the carbon black content in polyethylene, polypropylene, and polybutylene plastics, then we suggest you go with a carbon black content tester. Presto’s carbon black content apparatus is widely used for concluding the carbon black content in polypropylene and polyethylene materials. The test is applicable only to specimens where carbon is present in a free state. As per the standards, the carbon black content in the samples is calculated by measuring the difference in the mass of the sample after and before the procedure takes place in the apparatus. The laboratory instrument is designed as per IS 4984, ASTM D-1603, and IS 2530 standards to determine the content of plastics. It is the most important and protective material in plastic materials and more effective in polyethylene for performing a particular test. The method consists of analyzing the test specimen in a static atmosphere and considering the gravimetric difference. The glassware of the instruments is made up of the best quality alloys to keep away premature fusions. The temperature of the machine is controlled by built-in electronic controllers to avoid practically overshoots and better temperature stability. Presto’s Carbon Black Content Apparatus comprises the tubular furnace made up using mild steel material. The apparatus is incorporated with a nitrogen flow meter and a complete set of glass parts. Apart from this, there are two flasks to clutch solid ice. The machine is supplied with the main combustion boat and tubes fabricated using Quart glass. The properties of quartz glass help to bear higher temperatures as compared to that of hard borosil glass.

Its use with acrylic or other polar monomer modifications which might affect the accuracy is not recommended. Determinations of carbon black are made gravimetrically after pyrolysis of the sample under nitrogen. This test method is not applicable to compositions that contain nonvolatile pigments or filler other than carbon black. This test method is not applicable to materials containing brominated flame retardant additives at the end. The values stated in the SI unit are to be regarded as the standard. The values in parentheses are given for information only. It has been made in compliance with industrial standards like D883, and E177. This testing instrument by Presto is useful for control purposes and is required for the calculation of optical absorptivity.

This testing instrument will contain the following apparatus:

- The electric furnace is at least 20 cm long suitable for use with the tubing.

- High-Temperature Glass Combusting Tube of appropriate diameter and approximately twice as long as the furnace.

- Stopper two rubber or neoprene stoppers, to fit the tube. Unless the tube is fitted with ground joints and mating connectors.

- Glass Tubing, approximately 10 mm in diameter of sufficient amount, and matching rubber or plastic tubing for connections.

- Combustion Boat, approximately 8 by 1.9 by 1.3 cm. Glazed porcelain, quartz high silica glass, or platinum is suitable.

- Iron-Constantan Thermocouple and a potentiometer or millivolt meter suitable for determining temperatures in the range of 300 to 700 degrees C.

- Flow Meter suitable for measuring gas flow at rates of 1 to 10L/min.

- Traps, three glass traps with removable ground-glass connected heads and 10-mm diameter inner and connecting tubes.

- Drying Tube- A U-shaped drying tube, having an inside diameter of 20mm or larger, fitted with ground glass or neoprene stoppers.

- Glass Wool, Desiccator, with desiccant.

- Bunsen Burner, Balance An analytical balance having a sensitivity of 0.0001g

- Weights- a set of class S weights for use with the balance.

The procedure below assumes that the combustion tube can be easily removed from the furnace. If it is not the case, alternate methods of inserting and removing sample boats are acceptable as long as the temperature, purge time, and flow rate requirements are met.

- Assemble the apparatus. Both cold traps following the combustion tube shall contain trichloroethylene, but only the first need be cooled with solid carbon dioxide.

- Alternatively, the entire apparatus may be placed in a dioxide and in a fume hood and the two traps following the combustion tube are omitted.

- Fill the drying tube with anhydrous CaCl2 or another suitable desiccant. Hold between loose plugs of glass wool.

- Heat a clean combusting boat to red heat in a Bunsen flame then transfer the boat to the desiccator and allow it to cool over fresh desiccant for not less than 30 min.

- Remove the boat from the desiccator and weigh it to the nearest 0.0001 g. immediately place 1. 0 + 0.1 g of the ethylene plastic under teat in the boat and quickly weigh to the nearest 0.0001 g.

- Heat the furnace to a constant temperature of 600 degrees Celsius.

With the combusting tube remove from the furnace adjust the rate of nitrogen flow through the tube to 1.7 + 0.3 L/min. Open the inlet end of the combusting tube, quickly place the combusting boat with the sample into the tube positioned so the boat will be at the proper temperature when in the furnace. Close the inlet to the tube and allow the nitrogen to flow for a minimum of 5 min to purge oxygen from the system prior to placing the tube in the furnace. If the furnace is controlled by an external thermocouple, adjust the thermocouple so that the weld is in proximity to the boat. Insert the copper plug if this is used. Quickly place the tube into the furnace, close the furnace and allow heating to proceed for at least 15 min. Move the tube or furnace so that the boat is no longer in the heated zone of the furnace and allow 5 min for cooling while maintaining the flow of nitrogen. Remove the copper plug, if present, and the boat through the inlet end of the tube and allow it to cool in the desiccator for at least 30 min. Take care that the boat does not tube. Then quickly reweigh the boat and its contents to the nearest 0.0001 g. If carbon black measurements are to be made at values less than 1% then the sample boat with the residue of the tube furnace burn shall be placed in a muffle furnace for approximately 10 min to oxidize the carbon black. This is to correct for the presence of residual inorganic matter in the sample. After heating, cool the sample boat in a desiccator until it is at room temperature. Weigh the boat plus contents to the nearest 0.0001 g. In this way, you can commence the test.

Features of Carbon Black Content Apparatus

- This instrument is supplied with two separate glass flasks.

- The machine is equipped with a programmable P.I.D. temperature

- The machine is incorporated with quartz glass which can resist high temperature.

- The heater of the machine has a relatively low operating voltage that ensures the furnace is long-lasting.

Technical specifications

- The size of the furnace attached to the instrument is 6” x 6”x 6”.

- The temperature range can be set from ambient to 1150°C.

- The inner side of the instrument is made up of Stainless Steel, and the outer side is made up of Mild Steel duly powder coated.

- The laboratory equipment is supplied with some accessories, namely, Glass U Tube, Desiccator, Rubber tube – 1 no., Combustion tube, Combustion boat, Rotometer, Glass traps – 3nos., Glass end caps 2 nos.

- Single-phase power of 230V and 50 Hz.

- Display: Digital LED

- Temp. Range: From ambient to 1150 ° C

- Material of Construction: Inner Brick type and outer mild steel powder-coated

- Accessories: Desiccator, Glass U tube, Combustion tube, Combustion boat, Rotometer, Rubber tube, Glass end caps, Glass traps, Pore clain Boat, Aquartz Tube, Cork Plug

- Power Supply: Single Phase 220-240V AC, 50Hz.

- Control Method: Temp. Controller Digital

- Industry: Polymers/ Rubber/ Plastic