Frustrated by a product that does not meet its performance expectations because it slips or slides unexpectedly? Suppose, for a moment, that a superior, top-of-the-line product designed to offer the best grip possible fails users under real-world conditions, giving way to disappointed customers and financial losses. It is a common problem with potentially huge consequences. There is, however, one powerful tool that could keep you from falling into these traps: coefficient of friction testers.

The coefficient of friction tester is the most important device with respect to ensuring product performance, more specifically in industries where the end product requires grip and stability. It measures frictional properties between two surfaces, providing very critical data that helps to assess how materials will interact under different conditions. The manufacturers can therefore know what interactions to expect, hence making informed decisions on how to enhance their design of a product to avoid problems in performance that might lead to loss of profit.

What is a Coefficient of static Friction Tester?

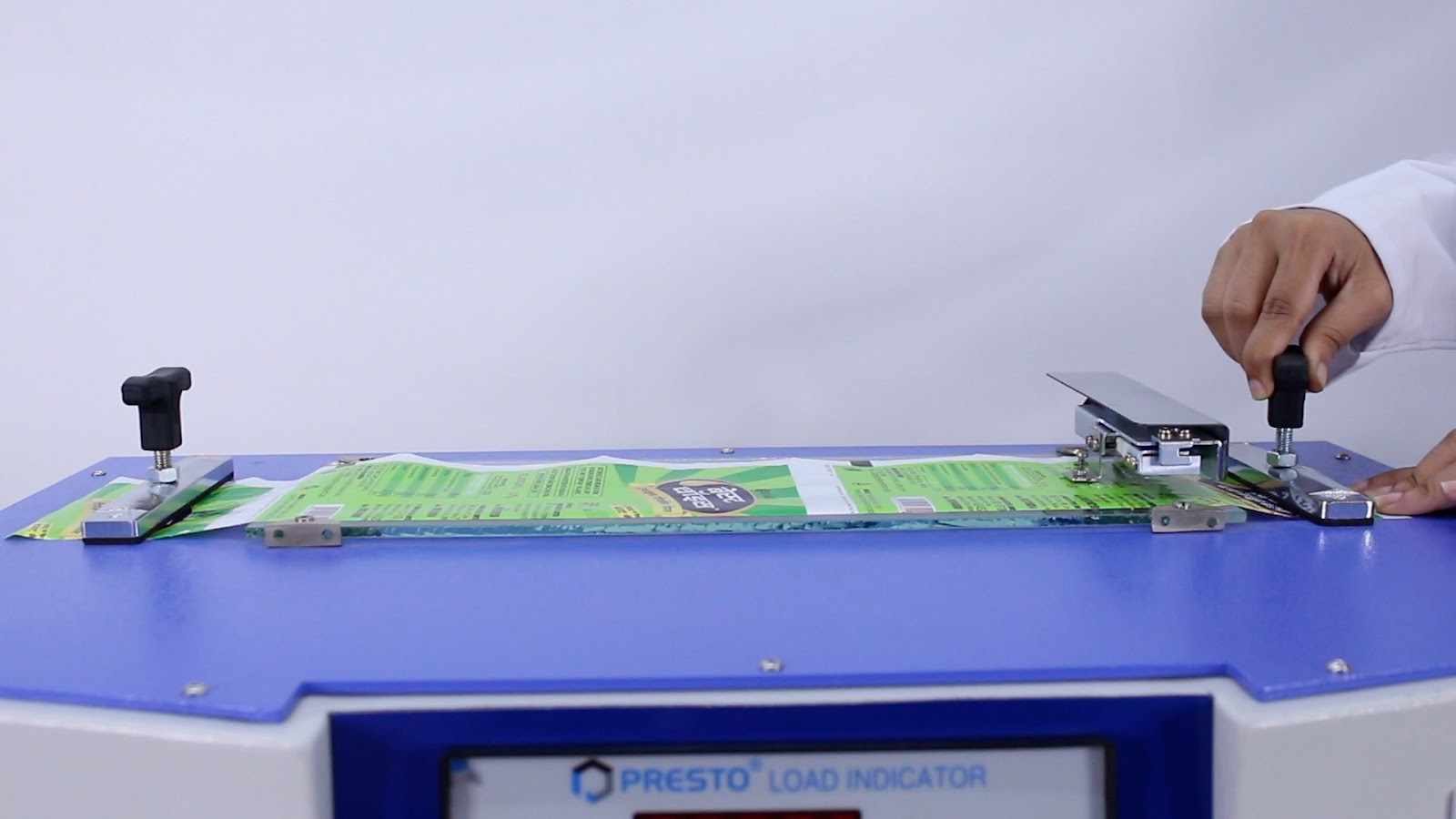

The coefficient of static friction tester is designed to measure the coefficient between two contacting surfaces. If one surface were to slide over another, it would quantify the amount of frictional resistance that occurs. The tester is designed to return exact and reliable data, which is very important in quality control and product development.

Characteristics of a Coefficient of Friction Tester

Characteristics of a Coefficient of Friction Tester

Test Fixture: The test fixture holds the sample materials against each other during testing. It normally comes with a flat, stable surface to provide accurate measurements.

Load Cell or Weight Formation: This component exerts a constant force to the sample materials. The load cell measures the amount of force needed to initiate and maintain sliding, which becomes very important in computing the COF.

Movable Stage or Slider: This moving stage or slider moves one material over another, whereby the frictional resistance encountered can be measured to determine the coefficient of friction.

Measurement System: The measurement system records data recorded during the test, including the force required to overcome friction. All this data will be used in calculating the COF Tester and assessing the performance of materials under test.

Control Interface: Through this interface, the user can set test parameters, start tests, and see results. Analysis and reporting software may also be added to the control interface.

How Does a Coefficient of Friction Tester Work?

The coefficient of friction tester operates on the following steps:

Sample Preparation: Materials or products to be tested are prepared and placed on the testing platform. This may also include surface characteristics, such as texture and finish, that are important in testing.

Application of Force: A continuous force is applied to one of the materials by the load cell or weighing mechanism. This force is used in pressing the sample materials together, ensuring they remain in contact throughout the test.

Sliding Test: A material is slid across the surface of the other material. The force applied to initiate and continue this sliding motion is measured and recorded.

Calculation of Data: The tester will calculate the coefficient of friction from the recorded force and normal force applied.

Test analysis: Such information is thus useful in pointing out the performance of the materials in real-time applications.

As a Manufacturer why do you need a Coefficient of static friction Tester?

Better product quality: Friction coefficient testers provide data for enhancing product design and material selection. Knowing the interaction between different materials and their performance under various conditions would enable manufacturers to optimize their products to function better and last longer. This develops higher-quality products with higher customer satisfaction ratings, thus safeguarding profit margins.

Preventing Costly Recalls and Rework: if the products have poor frictional properties for their intended use in service, then the manufacturer risks a costly recall and rework. Minimizing this risk, among others, is what the coefficient of friction tester will do by offering a clear pathway to enable manufacturers to test and improve products before they go to market. This forward-looking strategy will limit the possibility of defects and ensure that products work to their intended design, which will save time and money.

Meeting Industrial Standards: Friction and grip have, in most cases, specifications that are standard for the industry. The coefficient of friction tester helps a producer ensure that their product has complied with the standards, saving them from potential legal hassles and boosting their reputation as a quality and reliable product maker.

Manufacturing Process Optimization: Learned information from the test for friction can help in the optimization of manufacturing processes. For instance, adjusting surface treatments or material formulae according to the COF data may result in efficient production and more performant products.

The competitive market of today requires product performance and quality to be assured to protect your profits. Valuable among all is the coefficient of friction tester, which can procure very accurate and reliable data regarding frictional properties; hence, it helps a manufacturer avoid slipping and its associated financial losses. This tool, used for the assessment and refinement of products, allows improved performance and reduced risk of defects, thus protecting profit margins.

Ready to start protecting your profits and ramping up the performance of your products? Ensure that your products reach the highest standards of quality without grinding business to a halt over expensive issues by investing in a coefficient of friction tester today. Contact us now for more information on how our cutting-edge testers can help maintain quality and safeguard your bottom line.

Presto is Asia’s top manufacturer of co-efficient of friction testers and offers the best co-efficient of friction price of the materials. To conduct a free sample testing session for the use of this quality testing equipment, give us a call at +91-9210903903 or email us at info@prestogroup.com.