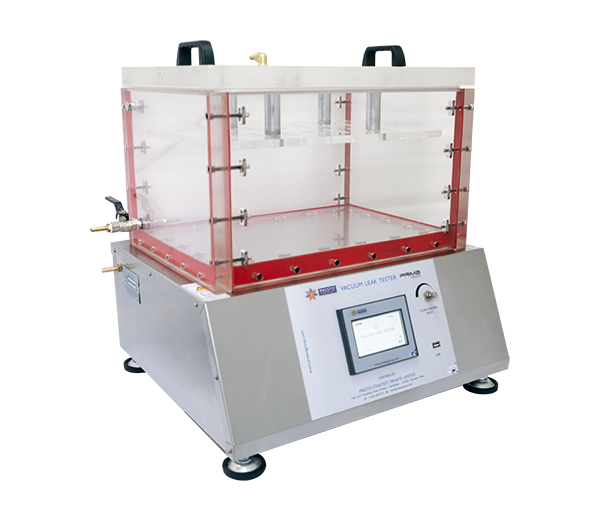

Vacuum Leak Tester - Prima (Dry & Wet)

4.67 out of 5

Do you want to get rid of those vacuum leaks? If yes, then we suggest you go with the Presto vacuum leak tester Prima series. It has been designed by keeping all industry standards in mind like ASTM F2338 – 09 (2013), ASTM D 4991-07 (2015). This is one of the best..read more

To operate the Presto vacuum leak tester, you need to place the specimen in the desiccator and close the lid. You can also turn on the machine by plugging in the main socket. When you turn on the machine then the HMI screen will also turn on. You need to place the specimen in the desiccator and close the lid tightly. After that, you will see several options on the HMI screen. You need to click on the profile settings and enter all the details. Whenever you set the values, make sure to set the vacuum value up to 600 mm Hg and hold the time value between 0-999 seconds. Click on the save button and start the test.

Users can observe that the vacuum incremental value started increasing on the display and after reaching the SET Vacuum Range, hold time will start automatically. During the hold, time Vacuum may drop. In this situation, the pump will start automatically. Hold time will pause during that time. If there is any leakage in the sample, the test material will spill out due to the vacuum created inside the desiccator. After the Hold time is finished, Vacuum will be released automatically. On completion of the test, Pass/Fail criteria window will appear on the screen. Now visually inspect the samples and click on a pass or fail accordingly. The data will save automatically in system memory. If there is a Leak Test failure, take another sample and continue the test procedure. Click on Main Menu History to view the previous test results. In this way, you can easily conduct the vacuum leak test with the help of the Presto Vacuum leak tester.

Features of Vacuum Leak Tester - Prima (Dry & Wet)

- HMI based Touchscreen Model

- Microprocessor-based controls for repeatability and accuracy

- Meets USP 28 packaging practice specification

- Air & Water as a testing medium

- Automatic sample testing through an easy vacuum mechanism

- Vacuum Pressure setting and timer Functions incorporated for repeatability and accuracy.

- Pass/ Fail criteria can be programmed.

- Changeable timer units in Hrs.: Min: Sec

- Inbuilt calibration facility

- Vacuum Pressure display incorporated in HMI for easy pressure monitoring

- Stainless steel body for corrosion resistance finish

- Program profile for selecting test parameters and performing the test.

- East data management. Users can create product identification, user name, vacuum hold time, set pressure, etc.

- Graph of Pressure vs. Time

- USB option available for storing test data and graph

- Print report with graph

- Data output in graphical and data record format.

- History data involves user name, time, date, vacuum hold time, etc

Technical specifications

- Equipment Range: up to 600 mm Hg

- Least Count: 10 mm Hg

- Inner chamber size: 310x310x310 mm

- Body Material: Stainless Steel or Mild steel powder-coated

- Controls: Pressure Monitoring & time integrated into HMI

- Display: HMI Touch Screen

- Electrical fuse: 5 amp

- Timing device: Inbuilt Timer

- Timer Least Count: 1 second

- Electrical supply: 5 amps. 220 V ± 15%. Single-phase AC

- Interface: RS232 /USB interface for data logging

- Time Range: Up to 999 seconds changeable to Hrs : min: sec

- Dimension HMI panel: 360 x 375 x 280 mm

Related Products

Preforms Perpendicularity Tester

Water Bath Digital

Vacuum Leak Tester for Bottles

Drop Tester

For More details & Information

Please fill this form

Vacuum Leak Tester - Prima (Dry & Wet)

4.67 out of 5

Do you want to get rid of those vacuum leaks? If yes, then we suggest you go with the Presto vacuum leak tester Prima series. It has been designed by keeping all industry standards in mind like ASTM F2338 – 09 (2013), ASTM D 4991-07 (2015). This is one of the best testing instruments that will help you to detect all the leakage from your testing specimen and improve its quality. This testing machine has been equipped with several amazing features that make it the preferable choice for various numbers of manufacturers of different industries.

Vacuum leaks can cause much damage to your products. They can damage the product or lead to contamination. This will result in poor quality production and loss of reputation. But, we at Presto understand what your product means to you. Therefore, we make sure that you will deliver accurate products to your customers. With Presto vacuum leak tester, you can easily check the seal integrity of various materials like foiled cups, PET bottles, etc. You can also make use of this testing instrument for detecting leaks in non-porous, rigid, and flexible packages. Vacuum leak testing is a critical step in the manufacturing process to ensure that your product will perform as intended. It's important for manufacturers to get this right because it can save you from having to scrap an entire batch of products - which could cost thousands of dollars. Our vacuum leak tester is designed to make this task easy and affordable, giving you peace of mind while saving time and money. Its easy-to-use mechanism makes it the number one choice for various manufacturers.

The Presto vacuum leak tester Prima series will give you fast and accurate testing results and can be available in various models with different specifications. With our certified testing machine, you can save money because there is no need for expensive replacement parts due to failed inspections or recalls from customers who have been exposed to contaminated food products during transit or storage via a leaking package. We understand that it is not easy to find leakage in packaging. Therefore, our testing machines are designed in such a way that they can detect even the smallest leaks present inside your product. Our testing instrument is made of high-quality material and is so affordable that you can easily deliver packages without any leaks in them.

Those who work in packaging, pharmaceuticals, or the food industry can easily make use of this testing instrument to detect the leaks in the package. Vacuum leak testing is a critical part of any manufacturing process. Thus, you need to take care of product leaks to make sure that the package delivered should be of very high quality. Most of the manufacturers make use of manual vacuum leak testing methods, which makes it difficult for them to detect the leaks. But with Presto leakage tester, you can easily place the specimen in a desiccator and switch on the testing machine to conduct the test. It comes with an HMI display to showcase the testing results. If your product fails in this test, then you can easily test it again.

To operate the Presto vacuum leak tester, you need to place the specimen in the desiccator and close the lid. You can also turn on the machine by plugging in the main socket. When you turn on the machine then the HMI screen will also turn on. You need to place the specimen in the desiccator and close the lid tightly. After that, you will see several options on the HMI screen. You need to click on the profile settings and enter all the details. Whenever you set the values, make sure to set the vacuum value up to 600 mm Hg and hold the time value between 0-999 seconds. Click on the save button and start the test.

Users can observe that the vacuum incremental value started increasing on the display and after reaching the SET Vacuum Range, hold time will start automatically. During the hold, time Vacuum may drop. In this situation, the pump will start automatically. Hold time will pause during that time. If there is any leakage in the sample, the test material will spill out due to the vacuum created inside the desiccator. After the Hold time is finished, Vacuum will be released automatically. On completion of the test, Pass/Fail criteria window will appear on the screen. Now visually inspect the samples and click on a pass or fail accordingly. The data will save automatically in system memory. If there is a Leak Test failure, take another sample and continue the test procedure. Click on Main Menu History to view the previous test results. In this way, you can easily conduct the vacuum leak test with the help of the Presto Vacuum leak tester.

Features of Vacuum Leak Tester - Prima (Dry & Wet)

- HMI based Touchscreen Model

- Microprocessor-based controls for repeatability and accuracy

- Meets USP 28 packaging practice specification

- Air & Water as a testing medium

- Automatic sample testing through an easy vacuum mechanism

- Vacuum Pressure setting and timer Functions incorporated for repeatability and accuracy.

- Pass/ Fail criteria can be programmed.

- Changeable timer units in Hrs.: Min: Sec

- Inbuilt calibration facility

- Vacuum Pressure display incorporated in HMI for easy pressure monitoring

- Stainless steel body for corrosion resistance finish

- Program profile for selecting test parameters and performing the test.

- East data management. Users can create product identification, user name, vacuum hold time, set pressure, etc.

- Graph of Pressure vs. Time

- USB option available for storing test data and graph

- Print report with graph

- Data output in graphical and data record format.

- History data involves user name, time, date, vacuum hold time, etc

Technical specifications

- Equipment Range: up to 600 mm Hg

- Least Count: 10 mm Hg

- Inner chamber size: 310x310x310 mm

- Body Material: Stainless Steel or Mild steel powder-coated

- Controls: Pressure Monitoring & time integrated into HMI

- Display: HMI Touch Screen

- Electrical fuse: 5 amp

- Timing device: Inbuilt Timer

- Timer Least Count: 1 second

- Electrical supply: 5 amps. 220 V ± 15%. Single-phase AC

- Interface: RS232 /USB interface for data logging

- Time Range: Up to 999 seconds changeable to Hrs : min: sec

- Dimension HMI panel: 360 x 375 x 280 mm