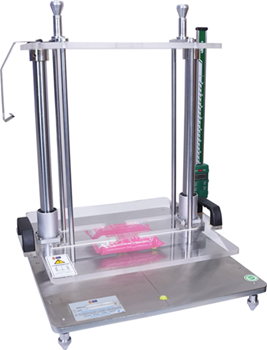

Laboratory Heat Sealer- (150 mm)

4.9 out of 5

The packaging industry is a very important and integral part of any business. Packaging is the key to providing an excellent customer experience. One of the effective testing machines that help you to accurately seal flexible packaging films is the Presto heat sealer. W..read more

The Presto Heat Sealer is an instrument used in laboratories to test the effect of high temperatures on different thermoplastic materials. It creates very high temperatures which are required for testing and studying the effects of these materials. To test your specimen effectively with Presto heat sealer, you need to follow the steps mentioned below:

- Turn ON the machine by plugging the mains socket of the machine into a 3 pin 15 amp socket. The PID controller will show some readings on the PV (Process Value) and SV (Set Value). Set the SV value on the PID controller and the value for test duration timing on the digital timer.

- Maintain the required temperature and pressure before placing the specimen between two sealers.

- After placing the specimen between the jaws press the push button or footswitch to move the jaw. The Specimen placed between two heated jaws in close contact helps to create a bond between two pieces of the specimen to seal the samples.

- The PID display will show an increase in temperature. After completion of pre-set time, the upper sealer will go back to its home position.

- Take out the specimen and analyze the changes in physical properties of the specimen.

In this way, you can effectively test the specimen and improve its quality.

Features of Laboratory Heat Sealer- (150 mm)

Presto heat sealers are very easy to use and have the capability to create very high temperatures for testing and studying the effect on different thermoplastic materials. With its unique testing features, you will be able to control temperature precisely and measure the result with a digital display of temperature. There are many other features as well of this testing instrument. They are discussed below:

- Easy installation.

- Low maintenance.

- High heating capacity from ambient to 2500 C.

- Advanced PID controller for effective temperature control.

- Auto tuning function provided with PID controller.

Technical specifications

- Equipment Range: Ambient to 350 degrees Celsius

- Working Range Ambient to 230 degrees C

- Sealing Size: 150 x 15 mm

- Sealing Jaw Material: EN 31 Hard and Temper

- Outer Body Material: Mild Steel Duly Powder Coated

- Least Count: 0.1 degrees C

- Repeatability: ±1 degree C

- Mode of Operation: Automatic with Digital timer and PID controller.

- Readout of Digital Preset Timer: Three-digit digital display

- Readout of PID temperature controller: Four-digit Digital display for easy temperature monitoring.

- Heat Source Cartridge Heater: (500 W each)

- Accuracy: ±2 degree C

- Temperature Control: PID temperature controller

- Timing device: Digital preset timer with a maximum limit of 99.9 Seconds

- Power supply control: Solid State Relay-25 amp

- Heat Sensor: PT-100, Platinum Resistance Temperature Detector (RTD)

- Electrical supply: 15 Amp. 220 V AC, 50 Hz, Single Phase

- Maximum Pressure (In Bar): 6 bars

- Dwell Time: 0.1 to 99.9 seconds

- Jaws: Straight Line (Knurling, Diamond, Plain are optional)

- Seal Pattern: Straight Line or Dotted

- Test Standard: ASTM F2029

Related Products

MFI TESTER NEO 2.0

Tearing Strength Tester

Digital Profile Projector with DRO

Air Bulge Tester

For More details & Information

Please fill this form

Laboratory Heat Sealer- (150 mm)

4.9 out of 5

The packaging industry is a very important and integral part of any business. Packaging is the key to providing an excellent customer experience. One of the effective testing machines that help you to accurately seal flexible packaging films is the Presto heat sealer. With the help of this testing instrument, you can easily seal various products like food, beverages, and much more. When the products get accurately sealed, then they become more secure and safe for consumption. Heat sealers are utilized in different industries such as food processing, medical, pharmaceuticals, etc., where they provide efficient sealing solutions with minimal investment on the client's side. In today's world, heat sealers in the packaging industry are becoming more and more popular. The main reason for this is because it provides a very effective way to protect your product from any possible damage during shipping or storage.

This testing device is used in testing laboratories for various research and analysis purposes. The instrument is capable of creating very high temperatures for testing and studying the effect on different thermoplastic materials that are used in plastic and packaging industries and other industrial laboratories. It is a tabletop model with a robust design that can efficiently work in harsh working conditions too. The main purpose of the Presto heat sealer is to seal one thermoplastic to another by applying heat and pressure. The direct contact method of heat sealing utilizes a constantly heated die or sealing bar to apply heat to a specific contact area or path to seal or weld the thermoplastics together. Heat sealing is used for many applications, including heat seal connectors, thermally activated adhesives, film media, plastic ports, or foil sealing. There is a PID controller provided with the instrument that is best for controlling the temperature with high accuracy. There is a dwell timer provided with the machine which is used for setting the testing time up to 99.9 seconds.

When you test and study the effect of high temperatures on different types of thermoplastic materials then you will be able to produce high-quality products with higher quality standards. Plus, it’s a great instrument to have if you want to do more research into the effects of high temperatures on plastics or other materials.

Most of the manufacturers make use of this testing instrument to seal the thermoplastic material and make sure that everything will be sealed properly. It’s a very important step in ensuring safety for everyone involved with these products. You can rest easy knowing that every single package will be tested by this machine before it leaves your warehouse. This advanced testing instrument can create very high temperatures for research and analysis purposes. It’s capable of sealing flexible packaging products, as well as other thermoplastic materials. This device is used in laboratories for various research and analysis purposes. You don’t have to worry about your product failing at the last minute because it wasn’t strong enough! With this heat sealer, you can be sure that your product will pass all tests, and if not, then you will be able to improve its quality.

This instrument is packed with a different set of features that makes your testing process easier and your business more productive. This machine is easy to install and needs low maintenance. You can adjust the heat accordingly with an advanced PID controller for effective product testing. You will also get auto-tuning function with a PID controller. The main unit of this testing machine contains a pneumatic cylinder, guide rod, pressure gauge, Pressure Regulator, RTD Sensor, Heater, Control Panel, Foot Rest, Lower Sealer, Upper Sealer, Guide Rod Bush, Flow Control valve ( Upper), Flow Control valve ( Lower), Test Pressure Port, Test Release Port, Cable Gland, Filter and Main Pressure Inlet Port. The outer body of this testing machine will be made with mild steel and duly powder-coated material. It will run automatically with a digital timer and PID controller. Many research laboratories use this device to study the effect of heat on various products made from different types of plastics. To know more about this testing instrument, you can give us a call now.

The Presto Heat Sealer is an instrument used in laboratories to test the effect of high temperatures on different thermoplastic materials. It creates very high temperatures which are required for testing and studying the effects of these materials. To test your specimen effectively with Presto heat sealer, you need to follow the steps mentioned below:

- Turn ON the machine by plugging the mains socket of the machine into a 3 pin 15 amp socket. The PID controller will show some readings on the PV (Process Value) and SV (Set Value). Set the SV value on the PID controller and the value for test duration timing on the digital timer.

- Maintain the required temperature and pressure before placing the specimen between two sealers.

- After placing the specimen between the jaws press the push button or footswitch to move the jaw. The Specimen placed between two heated jaws in close contact helps to create a bond between two pieces of the specimen to seal the samples.

- The PID display will show an increase in temperature. After completion of pre-set time, the upper sealer will go back to its home position.

- Take out the specimen and analyze the changes in physical properties of the specimen.

In this way, you can effectively test the specimen and improve its quality.

Features of Laboratory Heat Sealer- (150 mm)

Presto heat sealers are very easy to use and have the capability to create very high temperatures for testing and studying the effect on different thermoplastic materials. With its unique testing features, you will be able to control temperature precisely and measure the result with a digital display of temperature. There are many other features as well of this testing instrument. They are discussed below:

- Easy installation.

- Low maintenance.

- High heating capacity from ambient to 2500 C.

- Advanced PID controller for effective temperature control.

- Auto tuning function provided with PID controller.

Technical specifications

- Equipment Range: Ambient to 350 degrees Celsius

- Working Range Ambient to 230 degrees C

- Sealing Size: 150 x 15 mm

- Sealing Jaw Material: EN 31 Hard and Temper

- Outer Body Material: Mild Steel Duly Powder Coated

- Least Count: 0.1 degrees C

- Repeatability: ±1 degree C

- Mode of Operation: Automatic with Digital timer and PID controller.

- Readout of Digital Preset Timer: Three-digit digital display

- Readout of PID temperature controller: Four-digit Digital display for easy temperature monitoring.

- Heat Source Cartridge Heater: (500 W each)

- Accuracy: ±2 degree C

- Temperature Control: PID temperature controller

- Timing device: Digital preset timer with a maximum limit of 99.9 Seconds

- Power supply control: Solid State Relay-25 amp

- Heat Sensor: PT-100, Platinum Resistance Temperature Detector (RTD)

- Electrical supply: 15 Amp. 220 V AC, 50 Hz, Single Phase

- Maximum Pressure (In Bar): 6 bars

- Dwell Time: 0.1 to 99.9 seconds

- Jaws: Straight Line (Knurling, Diamond, Plain are optional)

- Seal Pattern: Straight Line or Dotted

- Test Standard: ASTM F2029