Precision has been the synonym for manufacturing long enough. It's justly so, demanding seals and joints to show total specifically in products that would be used in industries such as aerospace, automotive, or pharmaceuticals. Have you ever stopped and thought about how critical it this to be able to detect leaks in a system? Perhaps if you haven't, it is high time to get into the fascinating world of vacuum leak testing technologies!

What is a Vacuum Test?

I would start with what you all know about a vacuum test. A vacuum test can be defined as the process adopted while testing for leaks on different components according to an application of a vacuum test. In such a process, defects on the seals, welds, or materials identified may lead to failure in the field.

Why a Vacuum Test?

There are lots of benefits brought by the implementation of a vacuum test. It is highly sensitive and capable of detecting any leak, no matter how small or small the leakage may be. The method is ideal in situations where loss cannot be afforded. So, why do manufacturers think it is at the top?

Saves on Costs: Leak detection in the early stage saves product recalls cost or failure.

It gives quality to the final product: It ensures that the product is of the acceptable standard set by industry.

Regulatory Compliance: Mostly industries are quite strict regarding the purity of the product and therefore require such a test.

Running Vacuum Test

What is a running vacuum test? Imagine you are testing your system, and you want to see how the vacuum level would change over time. You therefore record how the vacuum level changes as the system runs. This would be the best method for use in dynamic systems whereby pressure changes can be caused by temperature fluctuations or operational stresses.

Major Benefits of Operating Vacuum Tests

Practical Operating Conditions: They simulate the practical conditions under which the system is to operate, hence you will have a closer approximation as regards its performance.

Predictive Maintenance: Monitoring of the vacuum continually by the manufacturer helps it predict when maintenance is required so as to prevent unwanted downtime

Better Safety: The capability to identify leaks before it is catastrophic failures would enhance the safety of operations.

How do you measure vacuum through a gauge?

Now that we are well-versed in the significance of vacuum tests, let us move along to talk about tool usage. How do you check a vacuum with a gauge? The tool used for checking is a vacuum gauge tester. It measures the pressure in a system of vacuum and lets you know if the vacuum level is within the limits.

Types of Vacuum Gauges

Mechanical Gauges: These are rugged and simple, and mostly work on a spring. They can be used for typical general applications.

Electronic Gauges: These are accurate and can be connected to a computer to collect data for further analysis.

Capacitance Manometers: Such gauges have high resolution. They can, therefore, measure extremely low vacuum levels and have applications that are sensitive.

Operating a Vacuum Gauge Tester

These are the steps of the procedure you should follow when you work with a vacuum gauge tester:

Gauging Up: Connect the gauge to the vacuum system through the most suitable fitting.

Applying Vacuum: Introduce a vacuum in the system through the use of a vacuum pump.

Monitor Readings: Observe the gauge once the system is near the minimum amount of vacuum needed. Provided that the reading on the gauge is stabilized, then there is a good chance that your seals are good.

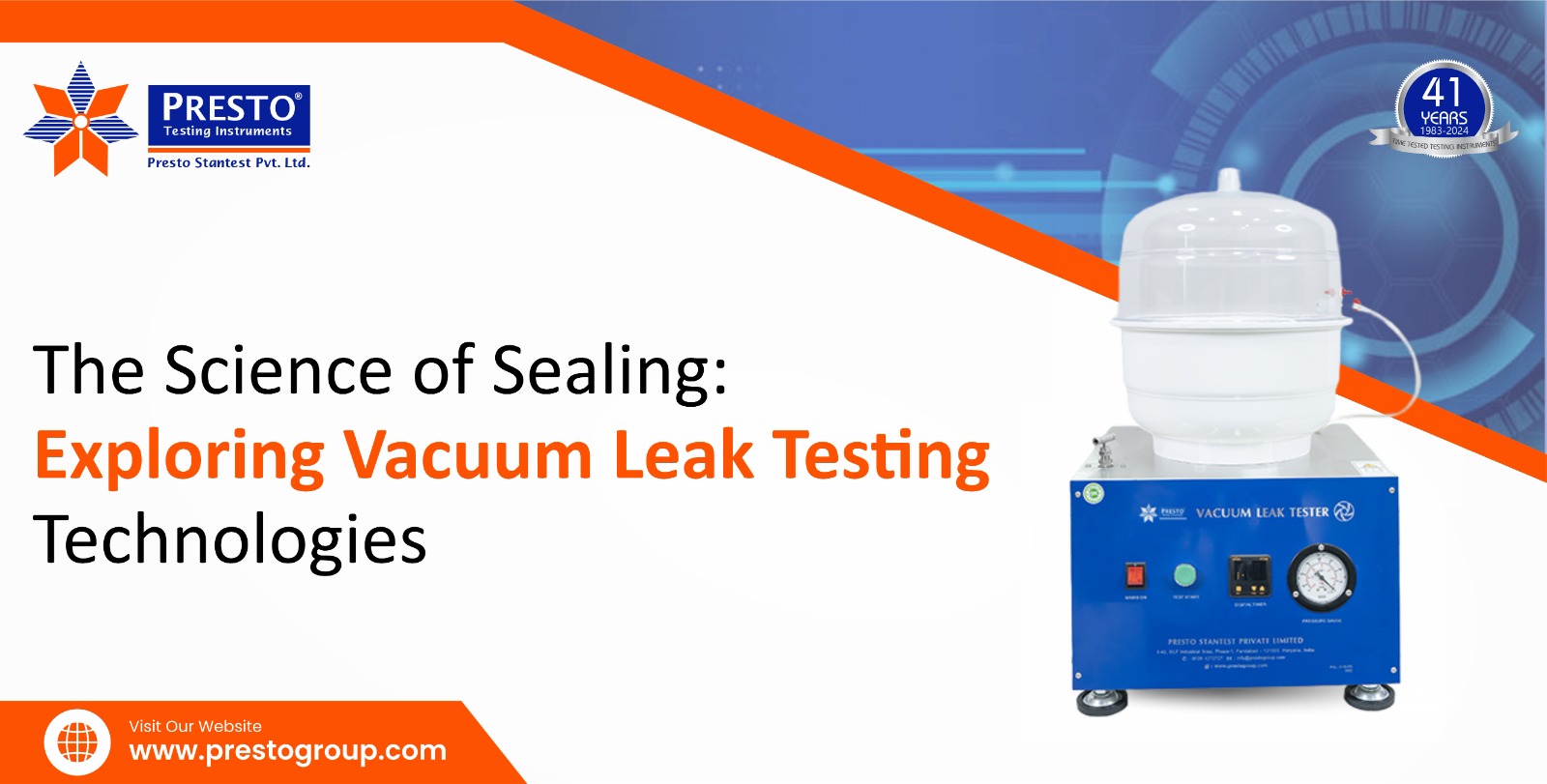

How Does the Vaccum Leak Tester Functions?

How Does the Vaccum Leak Tester Functions?

The Vacuum Leak tester functions by generating a vacuum and measuring how fast the pressure drop occurs over time.

How it works?

System Sealed: The system to be tested is sealed to prevent any outside air from penetrating.

Creation of Vacuum: A vacuum pump evacuates the system

Measurement of Fall in Pressure: The tester measures the time taken by a significant drop in pressure. If the pressure falls considerably, then there is a leak.

Types of Leak Testers

Bubble Leak Testers: These are those leak testers that make use of a fluid which creates bubbles whenever air leaks out, and thus indicates the leaks.

Helium Leak Detectors: Helium is introduced to the system; helium will leak better than air because helium is a very tiny molecule.

Mass Spectrometers: Highly sensitive detection of many gases; not limited to just those gases that might be leaking out from a leak.

Purchasing Criteria

Sensitivity and Range: Choose a tester that meets your minimum sensitivity requirements for applications.

What Type Tests You Need: Do you need a simple bubble test or a much more sophisticated helium leak detector?

Budget: Their costs range from several hundred dollars to thousands of dollars. What is your budget allocated to testing equipment?

Warranty and Support: The manufacturer's warranty and support would be most important to maintain the durability and life of the product.

Where to Buy

You can also find vacuum leak testers at several suppliers and manufacturers. Online marketplaces, local distributors, as well as specialized industrial equipment suppliers would be a good starting point. Do not spend too much time reading reviews and asking a few industry peers for some recommendations as needed.

FAQs

FAQs

What is a vacuum test?

A vacuum test is the leak detection that takes place in systems using vacuum and pressure monitoring.

What is a running vacuum test for?

Measure the operational vacuum level onsite in order to identify possible leaks or weaknesses.

How do you check a vacuum with a gauge?

You connect a vacuum gauge tester to the system, evacuate the air from it, and keep monitoring the pressure readings.

It is a leak detector by change of pressure in the vacuum system.

Knowledge of vacuum leak testing technologies would be a basic necessity, however, for manufacturers that claim to pride themselves in quality and reliability. Verifying the functional integrity and safety of your products using vacuum tests and gauges will ensure the value of your products. Do you want to buy a vacuum leak tester? What had been some of your challenges in using it in your current testing processes? Keep the dialogue going! Your input and experiences are invaluable in this fast-changing industry.

Phone: +91 9210 903 903

Mail: info@prestogroup.com