The highly changing landscape of manufacturing and material science gives birth to a variety of challenges that may impede productivity as well as quality. One of the prominent challenges is the assessment of stress and strain in materials; if not addressed properly, these result in catastrophic failures. In this direction, a polariscope is a sophisticated tool designed for accurate measurement and insight regarding material behavior.

Understanding the Polariscope: Breaking Down the Barriers in Material Analysis

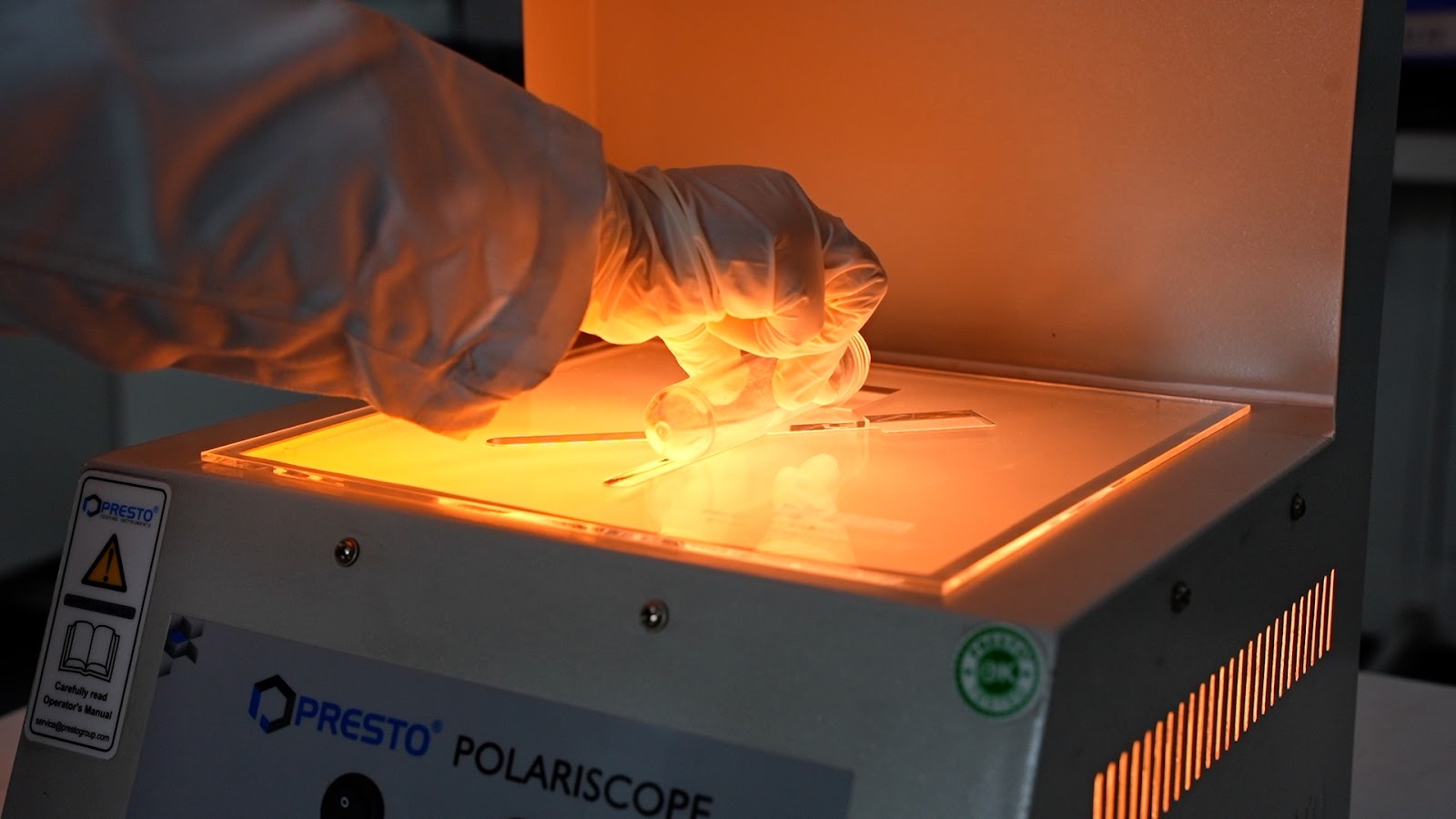

The polariscope is an optical tool used to analyze materials, particularly in examining how a material reacts to polarized light. This technique is very beneficial in identifying internal stresses, computing strain, and assessing material properties. It can change the game in industries that involve aerospace, automotive, or even construction where materials integrity is the key.

Presto: Your Trusted Quality Control Partner

With the name Presto coming to everyone's mind when talking about industrial instruments, the company has experience in delivering high-class testing solutions. Understanding the peculiar needs of its clients, Presto specializes in delivering precise and reliable instruments to ensure that industrialists concentrate on their main operations without a doubt. Quality and customer satisfaction are what make Presto the ideal partner for organizations looking forward to enhancing material analysis capabilities with the Polariscope.

Technical Features of Polariscope Strain Viewer

The technical features of the polariscope have to be understood by the potential buyer. The following aspects provide emphasis on it.

Optical Configuration: A polariscope strain viewer usually employs a monochromatic light source. The wavelength range used is between 400 to 700 nm. The configuration is an optical one. This would provide an accurate measurement of the strain.

Polariscope Price

The Polariscope Price depends on the model and specifications. The average is from ?50,000 to ?2,00,000. The investment would usually be recovered by superior quality assurance and material loss prevention.

-

Display: Large High resolution (7” Touch Screen)

-

Viewing Area: 260 X 240 mm

-

Power: 220V, Single phase, 50 Hz

Lights

-

CFL Light

-

sodium Light

Measuring Angle

-

45º and 90º (Auto Detect)

-

Standard Template: 1

-

Defect Chart: 1

-

Material: Mild Steel

-

Finish: Powder-coated Havel Gray/Blue

-

Dimensions: L 520 x W 585 x H 770 mm corrosion-resistant finish

Saving Resources Transforming Lives

It's no longer a matter of putting money into a Polariscope strain viewer but, in the most literal sense, revolutionizing an approach to material analysis. Here is how acquiring a Polariscope could change a life and save huge resources:

Reduced Material Waste: If points of stress in the materials can be identified properly, organizations would be able to reduce scrap generated during manufacturing processes. For example, if at present the company wastes 10 per cent of the material, the polariscope can limit it to 3%, saving roughly ?7,00,000 in a year only for material costs.

Enhanced Safety: The detection of failure modes even before they happen may lead to a safer workplace environment. The costs in case of accidents in the workplace run into crores, making the polariscope a very precious asset in risk management.

Improved Production Efficiency: The organization can reduce the time taken to make products by 15-20% since all materials will be stress-free and better suited for use. This reduces production delays and delivers the products on time to clients.

Better Quality of Products: The ability to conduct proper inspection will ensure products do not have chances of coming back as defective. This can save a company ?2,00,000 a year on returned products and reworks.

Labour Savings: With a polariscope strain viewer, fewer personnel are required for quality assurance processes as the instrument can provide faster and more accurate results. This can lead to annual savings of around ?5,00,000 in labour costs.

By using the polariscope's capabilities, organizations do not just preserve their materials and processes but instead create a more sustainable and profitable venture.

FAQs

1. What is the polariscope used for?

A polariscope is used to locate internal stresses within materials, measure strain, and analyze the optical properties of translucent materials.

2. How does a polariscope strain viewer function?

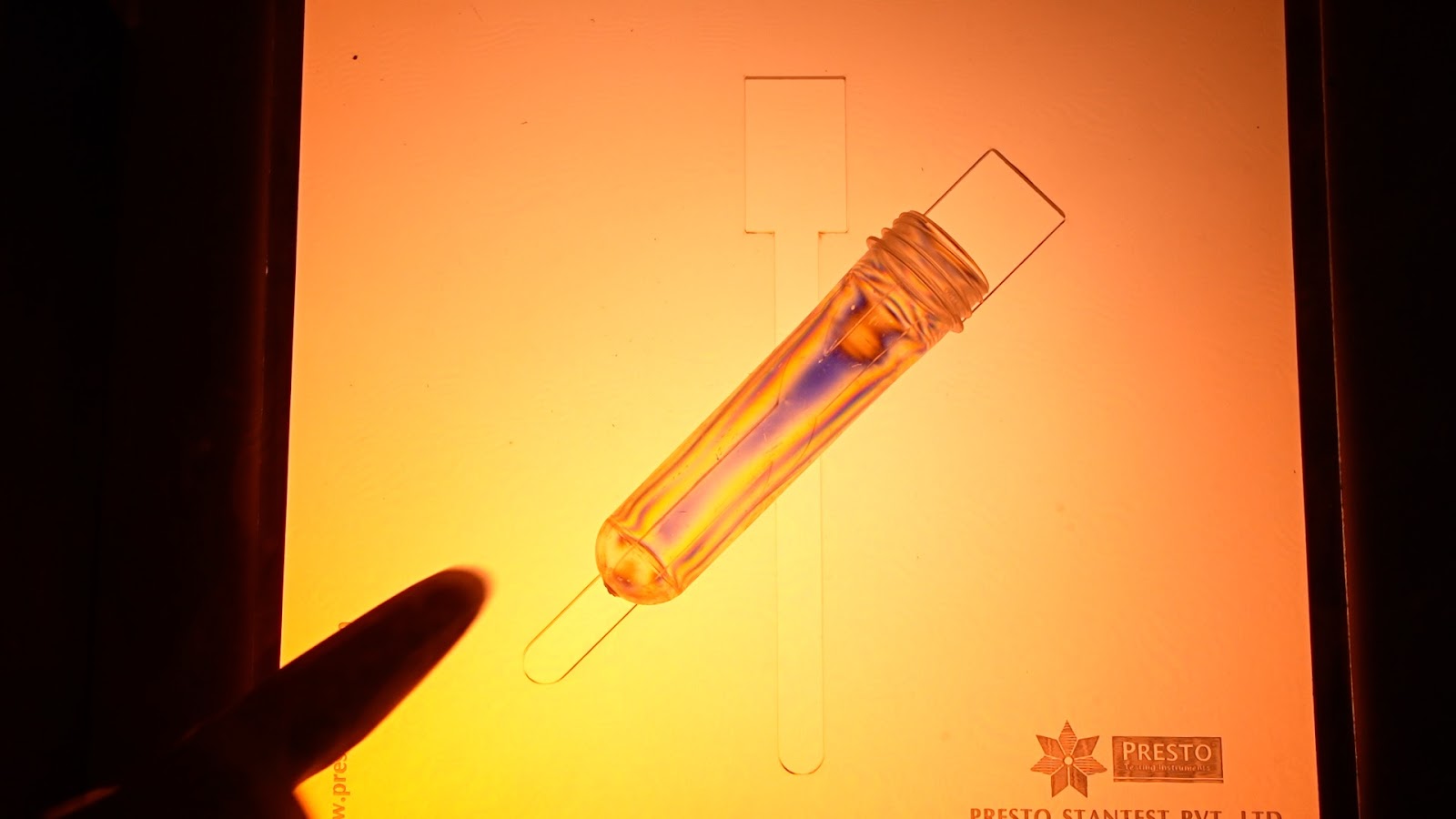

This uses polarized light to illuminate a material so the observer can see stress patterns because of how the material interacts with the polarized light.

3. Is a polariscope suitable for all materials?

Polariscopes are best suited for transparent materials like glass and plastics, though they can work with numerous other materials to determine internal stress.

Conclusion

The polariscope is an instrument, but it may be the means through which industrialists change the approach to analyzing materials. Investment in this technology would ensure the saving of enormous amounts of money and time as well as resources with the utmost standards of quality.

Don't let internal stresses compromise your materials and processes anymore. Contact Presto today to learn how our Polariscope can revolutionize your operations and give you the insights you need to succeed in your industry.