Air Bulge Tester

4.9 out of 5

The Air Bulge Tester is a precision-engineered instrument designed to evaluate the bulge resistance of packaging materials such as paper, films, foils, and laminates. Using controlled pneumatic pressure, the tester measures the durability and strength of materials, helping manufa..read more

-

Sample Placement

A sheet of the test material (paper, film, foil, or laminate) is clamped securely in the testing chamber using a pneumatic clamping system. This prevents slippage and ensures uniform pressure application. -

Air Pressure Application

Controlled compressed air pressure is gradually applied beneath the sample. The tester uses a precise pneumatic system to ensure steady and uniform pressure increase. -

Bulge Formation

As pressure rises, the material starts deforming (bulging) upward. The degree of bulge depends on the material’s strength and flexibility. -

Measurement

High-sensitivity sensors measure the pressure at which the material deforms or bursts. The maximum pressure sustained before failure is recorded as the bulge resistance value. -

Result Display

The tester provides accurate readings on a digital display, showing the air pressure value and bulge resistance of the sample. These results help determine material quality and durability.

Features of Air Bulge Tester

-

Rigid and durable construction for long-term performance

-

Pneumatic clamping system for secure sample holding

-

High-sensitivity pressure transducer for precise measurements

-

Adjustable air pressure for testing different grades of materials

-

Digital display for easy reading of results

-

Compact bench-top design for labs and industries

-

User-friendly operation with minimal maintenance

-

Conforms to international testing standards

Technical specifications

-

Model: PABT-300

-

Test Type: Pneumatic air pressure bulge resistance test

-

Pressure Range: 0 – 300 kPa (customizable)

-

Resolution: 0.1 kPa

-

Sample Material: Packaging films, paper, foils, laminates

-

Bulge Measurement Range: Up to 50 mm (customizable on request)

-

Clamping System: Pneumatic clamping for secure holding

-

Sensor: High-accuracy pressure transducer

-

Display: Digital pressure and bulge value display

-

Power Supply: 220 V, 50 Hz, single phase

-

Safety: Automatic pressure release & overload protection

-

Design: Compact bench-top structure, easy to operate

-

Compliance: Meets international packaging test standards

Related Products

Muffle Furnace – Digital Computerised

UV Light Accelerated Weathering Tester - Touch Screen

Bottle Perpendicularity Tester

Tensile Testing Machine – Digital Model

For More details & Information

Please fill this form

Air Bulge Tester

4.9 out of 5

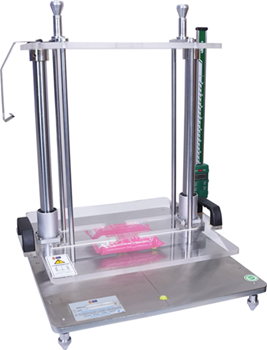

The Air Bulge Tester is a precision-engineered instrument designed to evaluate the bulge resistance of packaging materials such as paper, films, foils, and laminates. Using controlled pneumatic pressure, the tester measures the durability and strength of materials, helping manufacturers ensure high-quality, reliable packaging. Presto, a leading manufacturer and supplier in Faridabad, provides the PABT-300 model with advanced features for accurate and repeatable testing.

-

Sample Placement

A sheet of the test material (paper, film, foil, or laminate) is clamped securely in the testing chamber using a pneumatic clamping system. This prevents slippage and ensures uniform pressure application. -

Air Pressure Application

Controlled compressed air pressure is gradually applied beneath the sample. The tester uses a precise pneumatic system to ensure steady and uniform pressure increase. -

Bulge Formation

As pressure rises, the material starts deforming (bulging) upward. The degree of bulge depends on the material’s strength and flexibility. -

Measurement

High-sensitivity sensors measure the pressure at which the material deforms or bursts. The maximum pressure sustained before failure is recorded as the bulge resistance value. -

Result Display

The tester provides accurate readings on a digital display, showing the air pressure value and bulge resistance of the sample. These results help determine material quality and durability.

Features of Air Bulge Tester

-

Rigid and durable construction for long-term performance

-

Pneumatic clamping system for secure sample holding

-

High-sensitivity pressure transducer for precise measurements

-

Adjustable air pressure for testing different grades of materials

-

Digital display for easy reading of results

-

Compact bench-top design for labs and industries

-

User-friendly operation with minimal maintenance

-

Conforms to international testing standards

Technical specifications

-

Model: PABT-300

-

Test Type: Pneumatic air pressure bulge resistance test

-

Pressure Range: 0 – 300 kPa (customizable)

-

Resolution: 0.1 kPa

-

Sample Material: Packaging films, paper, foils, laminates

-

Bulge Measurement Range: Up to 50 mm (customizable on request)

-

Clamping System: Pneumatic clamping for secure holding

-

Sensor: High-accuracy pressure transducer

-

Display: Digital pressure and bulge value display

-

Power Supply: 220 V, 50 Hz, single phase

-

Safety: Automatic pressure release & overload protection

-

Design: Compact bench-top structure, easy to operate

-

Compliance: Meets international packaging test standards